Imagine walking through an industrial district. The air is thick, filled with fumes and emissions from nearby factories. You can’t help but wonder: Is breathing this air safe? What are the long-term health implications for workers and residents in the area? Is there a way to reduce industrial pollution without halting production?

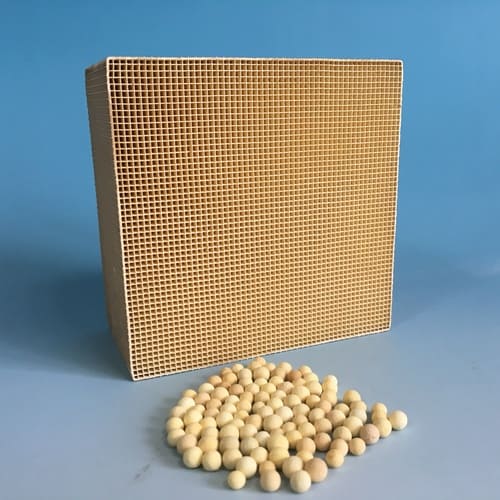

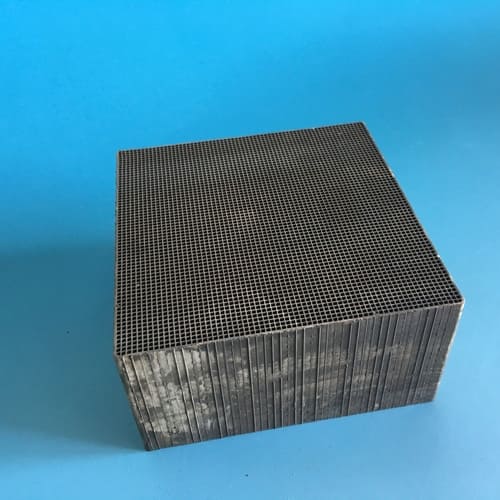

Monolith catalysts are powerful tools that dramatically improve air quality in industrial environments. Their unique structure—a solid, honeycomb-like framework coated with reactive materials—enables them to facilitate various chemical reactions that convert harmful pollutants into less toxic substances. Employed in numerous settings like power plants, petrochemical facilities, and manufacturing units, these catalysts are a crucial technology for emissions control and cleaner air.

Intrigued? Keep reading to find out how these unassuming materials are making an outsized impact on the quality of air we breathe.

What are Monolith Catalysts?

So, what exactly are monolith catalysts? These catalysts consist of a solid structure, often resembling a honeycomb, coated with catalytic materials like precious metals. The design maximizes surface area, allowing for efficient chemical reactions to take place. Studies show that these catalysts are highly effective in facilitating reactions needed for VOCs emission control.

How Do They Work?

You might be wondering how these catalysts work. Monolith catalysts function by facilitating chemical reactions that transform harmful pollutants like sulfur dioxide, nitrogen oxides, and volatile organic compounds into less harmful substances such as water and carbon dioxide. This happens when polluted air passes through the honeycomb structure of the catalyst.

What Types of Pollutants Do They Target?

Which pollutants do these catalysts target? Monolith catalysts are effective in reducing a variety of harmful pollutants commonly found in industrial emissions. This includes particulate matter, sulfur dioxide (SO2), nitrogen oxides (NOx), and volatile organic compounds (VOCs).

Why Are They Better Than Traditional Catalysts?

What makes monolith catalysts better than traditional pellet-based catalysts? The design of monolith catalysts reduces the pressure drop in reactors, thereby improving energy efficiency. Studies indicate that these catalysts can reduce pressure drop by up to 90% compared to pellet-based catalysts.

Can They Be Customized for Specific Industries?

Is customization an option? Absolutely. The catalytic materials used in monolithic catalysts can be tailored to suit specific industrial needs, square sizes are more popular and easier to install. This allows them to be versatile across different industries, from power plants to petrochemical factories.

How Do They Impact Worker Health?

A crucial point is their impact on worker health. Exposure to industrial pollutants can lead to numerous health issues like respiratory problems, cardiovascular diseases, and even cancer. By reducing harmful pollutants, monolith catalysts contribute to a healthier working environment.

What is Their Role in Regulatory Compliance?

Another important aspect to consider is regulatory compliance. With stricter emission norms being implemented globally, industries need effective solutions for pollution control. Monolithic catalysts help industries meet these regulations by efficiently reducing harmful emissions (source).

Conclusion

Monolith catalysts play a pivotal role in improving air quality in industrial environments. From facilitating chemical reactions that break down pollutants to being customizable for various industrial applications, they are invaluable assets for both pollution control and regulatory compliance. By using these catalysts, industries can make significant strides toward cleaner air and a healthier future for us all.