Have you ever wondered how industries manage to control the emission of harmful gases? Or pondered how they adapt to the diverse and challenging environment within which they operate? Within the complicated mechanics of industrial operations, one solution that stands out for its efficacy and adaptability is the use of monolithic catalysts.

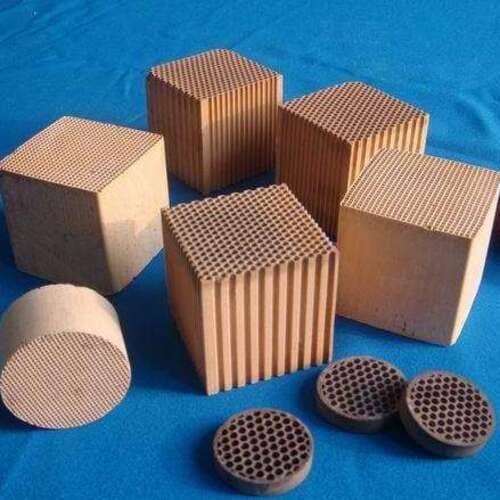

Monolithic catalysts are essentially honeycomb-like structures embedded with active catalyst materials, whose main job is to speed up chemical reactions. But here’s the kicker: can these monolithic catalysts be customized for specific industrial applications?

The simple answer is yes. Customization of monolithic catalysts is not just a theoretical concept but a practical reality in many industries today. Monolithic catalysts can be tailored to handle different chemical reactions by modifying their composition, structure, and active catalytic materials. This flexibility allows industries to use these catalysts for a wide range of applications, from controlling Volatile Organic Compounds (VOCs) in chemical plants to reducing nitrogen oxide emissions in power plants.

Continuing with the topic, it’s easy to see how customization of monolithic catalysts can be a game-changer in industrial emission control. Let’s delve deeper.

How does the customization process work?

Customization of monolithic catalysts involves modifying the catalyst’s composition, structure, and active materials to suit a specific application. For instance, the use of different catalyst materials like platinum, palladium, or rhodium can help target specific pollutants. Further, by changing the structure or composition of the monolithic substrate, industries can optimize the catalyst’s performance for their specific needs. For instance, a denser honeycomb structure might be used for applications requiring high surface area, while a more open structure might be used for applications needing high gas flow rates.

Why is customization essential for different industries?

Different industries have different needs when it comes to emission control. For instance, a petrochemical plant dealing with high levels of VOCs might require a different catalyst than a power plant looking to reduce nitrogen oxide emissions. Customizing monolithic catalysts allows these catalysts to be fine-tuned for the specific reaction they are meant to catalyze. In turn, this leads to better performance and efficiency.

What are the challenges in customizing monolithic catalysts?

While customization offers numerous benefits, it’s not without its challenges. The process of embedding the active catalyst material into the monolithic structure requires precise control to ensure even distribution. Furthermore, the use of precious metals like platinum in these catalysts can make them expensive to produce. Despite these challenges, the benefits of customized monolithic catalysts in controlling industrial emissions often outweigh the costs.

Can customization make monolithic catalysts more effective in controlling emissions?

Undoubtedly, yes. Customization can improve the efficiency and effectiveness of monolithic catalysts in controlling emissions. By modifying the catalyst to better match the specific reaction it is meant to catalyze, the catalyst can provide better conversion rates, leading to fewer harmful emissions.

Conclusion

In the end, the question isn’t so much whether monolithic catalysts can be customized, but how we can best customize them to meet the unique needs of each industry. Customization is a powerful tool that, when used properly, can significantly enhance the efficiency and effectiveness of monolithic catalysts in controlling industrial emissions. Through careful selection and modification of catalyst materials, SKY emission can tailor these versatile tools to better serve our environment and our health.

Please note that the information about catalyst materials and their effects on industrial emissions is based on this research from ScienceDirect. The customization process and its implications on efficiency are discussed in this publication on Springer.