Imagine a steel mill operating at full capacity, producing tons of high-quality products daily. Meanwhile, volatile organic compounds (VOCs) escape into the air, threatening environmental compliance and adding to regulatory pressures. How can industries strike a balance between production and sustainability? Are VOC catalysts the ultimate solution to reduce emissions?

VOC catalysts play a vital role in managing emissions from aluminum coil and steel mills. These industries emit large quantities of VOCs during production processes, which, if untreated, contribute significantly to air pollution. Leveraging advanced catalytic technologies ensures that harmful emissions are transformed into less hazardous substances, keeping industries compliant with environmental regulations and reducing their ecological footprint.

But what exactly are VOC catalysts, and how do they work in these industries? Let’s dive deeper.

What Are VOC Catalysts, and Why Are They Essential in Aluminum and Steel Mills?

VOC catalysts are specialized materials designed to facilitate chemical reactions that convert harmful VOCs into carbon dioxide (CO₂) and water vapor. These emissions typically originate from processes such as coating, curing, and surface treatments in aluminum coil and steel mill operations.

Without proper controls, VOCs can cause air pollution, contribute to smog formation, and pose health risks. Strict environmental regulations, like the Clean Air Act, demand that industries adopt technologies to limit VOC emissions. Failing to comply can result in hefty fines and damage to a company’s reputation.

VOC catalysts are tailored to meet the unique challenges of high temperatures, varying VOC concentrations, and harsh operating conditions. By installing catalytic converters, companies can efficiently break down VOCs, ensuring compliance while maintaining production efficiency.

How Do VOC Catalysts Work in Industrial Applications?

Key Processes in Aluminum Coil and Steel Mills

- Coating Lines: Coatings applied to steel and aluminum release VOCs during drying and curing.

- Annealing Furnaces: High temperatures in annealing can release hydrocarbons into the atmosphere.

- Cleaning and Pretreatment: VOCs are emitted during surface cleaning processes involving solvents.

In these processes, VOC catalysts act by:

- Oxidizing VOCs into CO₂ and water vapor.

- Operating at lower temperatures compared to other oxidation methods, saving energy.

- Enhancing the durability and efficiency of emission control systems.

Advantages of Using VOC Catalysts in Aluminum and Steel Mills

- Compliance with Environmental Regulations VOC catalysts help industries meet strict standards set by organizations such as the Environmental Protection Agency (EPA). Many regional authorities also mandate catalytic solutions to minimize industrial emissions.

- Cost Efficiency Though the initial installation cost might seem high, VOC catalysts reduce energy consumption by operating at lower temperatures. They also have a longer lifespan, leading to reduced maintenance costs.

- Improved Air Quality By significantly lowering VOC emissions, these catalysts contribute to cleaner air, benefiting both the environment and public health.

- Adaptability Modern VOC catalysts can handle diverse VOC compositions and are suitable for high-capacity industrial systems.

How to Choose the Right VOC Catalyst for Your Plant?

Factors to Consider:

- VOC Composition: Different processes emit different VOCs. Choose a catalyst suited for your emissions profile.

- Operating Conditions: Consider factors such as temperature, flow rate, and pressure.

- System Design: Ensure compatibility with your existing emission control systems.

Consulting with experienced suppliers of VOC catalysts, such as Skyemission, ensures that you select the best solution tailored to your facility’s needs.

Frequently Asked Questions About VOC Catalysts

How do VOC catalysts compare to thermal oxidizers?

VOC catalysts operate at lower temperatures, making them more energy-efficient than thermal oxidizers. While thermal oxidizers can handle higher VOC concentrations, catalysts are better for long-term cost savings and environmental compliance.

Are VOC catalysts suitable for all VOC types?

Most VOC catalysts can handle hydrocarbons, aldehydes, and alcohols. However, some specialized VOCs may require customized solutions.

What maintenance is required for VOC catalysts?

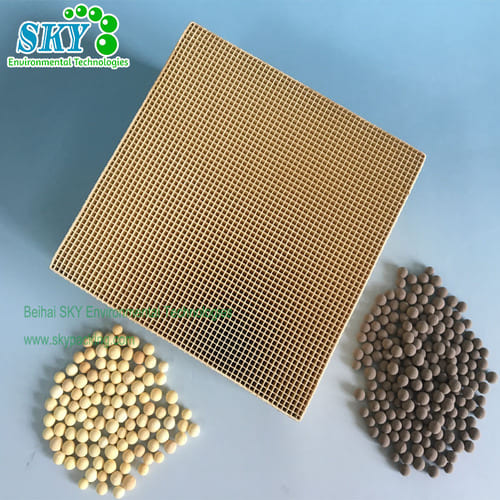

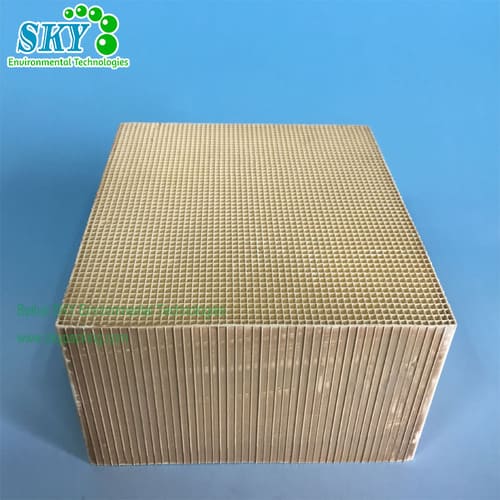

Periodic cleaning and inspections are necessary to maintain efficiency. High-quality catalysts, such as those with ceramic honeycomb carriers, often require less frequent servicing.

Conclusion

VOC catalysts are indispensable for aluminum coil and steel mills aiming to achieve environmental compliance while maintaining operational efficiency. They ensure reduced VOC emissions, cost savings, and adherence to global and local regulations. Investing in the right catalytic solutions is not just about compliance—it’s about embracing sustainability and protecting the future.

For industries seeking reliable emission control solutions, VOC catalysts are the way forward. Contact Skyemission today to explore cutting-edge catalytic technologies tailored to your needs.