Are you experiencing decreased performance in your vehicle? Does it emit excessive smoke and emit a strong odor? These are signs that your vehicle’s DPF (Diesel Particulate Filter) may be failing. The DPF filter plays a vital role in reducing harmful emissions and keeping your engine running smoothly. In this comprehensive guide, we will provide you with everything you need to know about DPF filter replacement. From understanding how the DPF filter works to recognizing common signs of failure, we’ve got you covered. We’ll also walk you through the replacement process, ensuring you have all the information you need to make informed decisions and get your vehicle back on the road in no time. Don’t let a failing DPF filter compromise the performance and safety of your vehicle. Read on to discover the ultimate guide on DPF filter replacement.

How do DPF filters work?

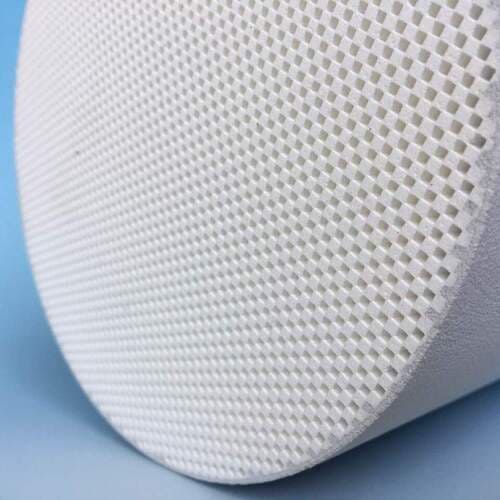

Diesel Particulate Filters (DPFs) are an essential component of modern diesel engines, designed to reduce the emission of harmful particulate matter (PM) into the environment. These filters work by trapping and storing the soot and particulates generated during the combustion process. The trapped particles are then periodically burned off, or “regenerated,” through a process that raises the temperature of the filter to high levels, effectively cleaning it and allowing it to continue functioning effectively.

The DPF is typically located in the exhaust system, downstream of the engine. As the exhaust gases pass through the filter, the particulate matter is captured and accumulated within the filter’s porous structure. This trapping process continues until the filter reaches a certain level of saturation, at which point the regeneration process is initiated. During regeneration, the engine management system increases the temperature of the exhaust gases, causing the trapped particulates to burn off and be expelled from the filter, leaving it clean and ready to continue its filtration duties.

The regeneration process can occur passively, where the high temperatures of normal driving conditions are sufficient to trigger the regeneration, or actively, where the engine management system initiates a more intense regeneration cycle to clean the filter. The frequency of regeneration depends on various factors, such as driving conditions, engine load, and the amount of particulate matter being generated. Regular maintenance and monitoring of the DPF system are crucial to ensure its proper functioning and the overall efficiency of the vehicle’s emissions control system.

Signs of a failing DPF filter

As the DPF filter accumulates particulate matter over time, it can become clogged, leading to a range of performance issues and warning signs. It’s important to be aware of these signs so that you can take prompt action to address the problem and prevent further damage to your vehicle.

One of the most common signs of a failing DPF filter is decreased engine performance. As the filter becomes clogged, the backpressure in the exhaust system increases, making it more difficult for the engine to expel exhaust gases. This can result in a noticeable loss of power, sluggish acceleration, and reduced fuel efficiency.

Another telltale sign of a DPF filter issue is excessive smoke or soot emissions from the vehicle’s exhaust. If you notice a significant increase in the amount of black or gray smoke coming from your vehicle, it’s a clear indication that the DPF filter is not functioning as it should, and the trapped particulates are being expelled into the environment.

In addition to decreased performance and visible smoke, a failing DPF filter may also cause a strong, unpleasant odor from the exhaust. This odor is often described as a “rotten egg” or “sulfurous” smell, and it’s a result of the incomplete combustion of the trapped particulates. If you notice this distinctive odor, it’s a sign that you should have your vehicle’s DPF system inspected and serviced as soon as possible.

Importance of regular maintenance and cleaning

Maintaining and cleaning your DPF filter is crucial to ensuring its longevity and the overall efficiency of your vehicle’s emissions control system. Neglecting the DPF filter can lead to a range of problems, including decreased performance, increased fuel consumption, and even permanent damage to the filter itself.

One of the primary reasons for regular DPF maintenance is to prevent the filter from becoming clogged. As the filter traps particulate matter, it can gradually become saturated, reducing its ability to effectively filter the exhaust gases. This can lead to increased backpressure in the exhaust system, which can cause a loss of engine power and efficiency.

In addition to clogging, a neglected DPF filter can also lead to the accumulation of ash, a byproduct of the regeneration process. Over time, this ash can build up within the filter, reducing its overall capacity and efficiency. Regular cleaning and maintenance can help to remove this ash buildup, ensuring that the filter continues to function at its best.

Neglecting DPF maintenance can also have long-term consequences for your vehicle’s engine and emissions control system. A clogged or malfunctioning DPF filter can cause increased fuel consumption, as the engine has to work harder to expel the exhaust gases. This can lead to higher fuel costs and increased emissions, which can be detrimental to the environment and potentially result in fines or penalties in some jurisdictions.

DIY DPF filter cleaning methods

While regular maintenance and cleaning of your DPF filter is essential, there are also DIY methods that you can use to help extend the life of your filter and maintain its optimal performance. These methods can be a cost-effective alternative to professional cleaning or replacement, but it’s important to follow the manufacturer’s recommendations and safety guidelines carefully.

One of the most common DIY cleaning methods is the use of a DPF cleaning additive. These specialized additives are designed to be added to the fuel tank, where they are then burned off during the normal combustion process. As the additive passes through the DPF filter, it helps to break down and remove the accumulated particulate matter, effectively cleaning the filter from the inside out.

Another DIY cleaning method is the use of a DPF filter cleaning tool or machine. These devices are designed to be connected to the vehicle’s exhaust system, where they can perform a more intensive cleaning process. The cleaning tool or machine typically uses high-pressure air or specialized cleaning solutions to dislodge and remove the accumulated particulate matter and ash from the DPF filter.

It’s important to note that while these DIY cleaning methods can be effective, they should not be used as a substitute for regular professional maintenance and inspection. Improper cleaning or the use of unsuitable cleaning products can potentially damage the DPF filter or other components of the emissions control system. Always follow the manufacturer’s instructions and consult with a qualified automotive technician if you have any doubts or concerns about the condition of your DPF filter.

When to replace a DPF filter

Determining when to replace a DPF filter can be a complex task, as the lifespan of the filter can vary depending on a variety of factors, such as driving conditions, maintenance history, and the overall condition of the vehicle’s emissions control system. However, there are some general guidelines and warning signs that can help you identify when it’s time to consider a DPF filter replacement.

One of the primary indicators that a DPF filter may need to be replaced is a persistent and significant increase in backpressure in the exhaust system. As the filter becomes clogged with particulate matter and ash, the backpressure in the system will gradually increase, leading to decreased engine performance, reduced fuel efficiency, and potentially even the triggering of warning lights on the vehicle’s dashboard.

Another sign that a DPF filter may need to be replaced is the inability to successfully complete a regeneration cycle. If the engine management system is unable to raise the temperature of the filter to the required levels to burn off the accumulated particulates, it can indicate that the filter is no longer functioning effectively and may need to be replaced.

In some cases, the DPF filter may also need to be replaced due to physical damage or deterioration. If the filter has been subjected to extreme temperatures, corrosion, or other forms of physical stress, it may no longer be able to effectively trap and filter the particulate matter, necessitating a replacement.

It’s important to note that the recommended replacement interval for a DPF filter can vary widely depending on the manufacturer and the specific vehicle model. Some manufacturers may recommend replacing the filter every 100,000 miles or so, while others may suggest a longer lifespan. Consulting your vehicle’s owner’s manual or speaking with a qualified automotive technician can help you determine the appropriate replacement interval for your DPF filter.

Choosing the right DPF filter replacement

When it comes time to replace your vehicle’s DPF filter, it’s crucial to select the right replacement part to ensure optimal performance and compatibility with your vehicle’s emissions control system. Choosing the wrong DPF filter can lead to a range of issues, including decreased engine efficiency, increased fuel consumption, and even potential damage to other components in the exhaust system.

One of the most important factors to consider when selecting a DPF filter replacement is the specific make, model, and year of your vehicle. DPF filters are typically designed and engineered to fit specific vehicle applications, and using a filter that is not compatible with your vehicle can result in fitment issues and potential performance problems.

In addition to vehicle compatibility, it’s also important to consider the quality and construction of the DPF filter itself. High-quality filters are typically made from durable materials, such as cordierite DPF or SiC DPF substrates, and are designed to withstand the high temperatures and pressures of the exhaust system.

Another factor to consider when selecting a DPF filter replacement is the filter’s capacity and efficiency. Some filters are designed to handle higher levels of particulate matter, while others may be better suited for lighter-duty applications. Choosing a filter that is appropriately sized for your vehicle’s engine and driving conditions can help ensure optimal performance and longevity.

When in doubt, it’s always best to consult with a qualified automotive technician or the vehicle’s manufacturer to ensure that you are selecting the right DPF filter replacement for your specific vehicle and driving needs. Taking the time to make an informed decision can help you avoid costly problems down the road and ensure the continued efficiency and performance of your vehicle’s emissions control system.

Steps to replace a DPF filter

Replacing a DPF (Diesel Particulate Filter) filter can be a complex and time-consuming task, but it’s an essential maintenance procedure that can help to ensure the continued efficiency and performance of your vehicle’s emissions control system. If you’re comfortable working on your vehicle and have the necessary tools and equipment, you may be able to tackle the DPF filter replacement process yourself. However, it’s important to follow the manufacturer’s instructions and safety guidelines carefully to avoid any potential issues.

The first step in the DPF filter replacement process is to properly prepare your vehicle. This typically involves disconnecting the battery, allowing the engine and exhaust system to cool completely, and safely raising the vehicle to provide access to the DPF filter. Once the vehicle is properly prepared, you can begin the process of removing the old DPF filter.

Depending on the specific make and model of your vehicle, the process of removing the old DPF filter may involve disconnecting various hoses, sensors, and other components in the exhaust system. It’s important to take note of the orientation and placement of these components, as they will need to be reinstalled correctly when installing the new DPF filter.

Once the old DPF filter has been removed, you can begin the process of installing the new filter. This may involve aligning the filter correctly in the exhaust system, reconnecting any hoses or sensors, and ensuring that all connections are secure and properly tightened. It’s also important to follow any specific instructions or procedures provided by the filter manufacturer to ensure a proper and effective installation.

After the new DPF filter has been installed, you’ll need to reset any diagnostic codes or warning lights that may have been triggered by the filter replacement process. This may involve using a diagnostic tool or following specific procedures outlined in the vehicle’s owner’s manual. It’s also a good idea to perform a test drive to ensure that the new DPF filter is functioning properly and that there are no other issues with the vehicle’s emissions control system.

Throughout the DPF filter replacement process, it’s important to take safety precautions and wear appropriate personal protective equipment (PPE), such as gloves and eye protection, to avoid any potential hazards. Additionally, it’s always a good idea to consult with a qualified automotive technician if you have any doubts or concerns about your ability to safely and effectively replace the DPF filter on your vehicle.

Common mistakes to avoid during DPF filter replacement

Replacing a DPF (Diesel Particulate Filter) filter can be a complex and delicate process, and it’s important to be aware of the common mistakes that can occur during the replacement process. Avoiding these mistakes can help to ensure the successful installation of the new filter and the continued efficient operation of your vehicle’s emissions control system.

One of the most common mistakes during DPF filter replacement is the improper handling or installation of the new filter. This can include dropping or damaging the filter, failing to align it correctly in the exhaust system, or not securing the connections properly. Improper handling or installation can lead to leaks, reduced filtration efficiency, and even potential damage to other components in the exhaust system.

Another common mistake is the failure to properly reset or clear any diagnostic codes or warning lights that may have been triggered by the DPF filter replacement. If these codes and lights are not properly reset, they can continue to cause issues with the vehicle’s emissions control system and potentially lead to further problems down the road.

Additionally, some vehicle owners may attempt to bypass or disable the DPF filter altogether, either to avoid the cost of replacement or to improve the vehicle’s performance. However, this is generally not recommended, as it can lead to significant increases in harmful emissions and may result in legal issues or penalties in some jurisdictions.

Finally, one of the most critical mistakes to avoid during DPF filter replacement is the use of incompatible or low-quality replacement parts. As mentioned earlier, it’s essential to select a DPF filter that is specifically designed and engineered for your vehicle’s make, model, and year. Using the wrong filter can result in fitment issues, decreased performance, and potentially even damage to other components in the exhaust system.

By being aware of these common mistakes and taking the necessary precautions during the DPF filter replacement process, you can help to ensure the successful installation of the new filter and the continued efficient and safe operation of your vehicle’s emissions control system.

Conclusion: Ensuring the longevity of your DPF filter

In conclusion, the DPF (Diesel Particulate Filter) is a critical component of modern diesel vehicles, responsible for reducing the emission of harmful particulate matter into the environment. Maintaining and replacing this filter is essential for ensuring the continued performance, efficiency, and environmental compliance of your vehicle.

Throughout this comprehensive guide, we’ve explored the inner workings of the DPF filter, the signs of a failing filter, the importance of regular maintenance and cleaning, and the steps involved in replacing the filter. We’ve also discussed the importance of selecting the right replacement filter and avoiding common mistakes during the replacement process.

By understanding the role of the DPF filter and taking proactive steps to maintain and replace it as needed, you can help to ensure the longevity of this critical component and the overall health of your vehicle’s emissions control system. Regular inspections, timely replacements, and adherence to the manufacturer’s recommendations can all contribute to the long-term performance and reliability of your diesel-powered vehicle.

Remember, addressing DPF filter issues promptly is not only important for the health of your vehicle but also for the environment and your own compliance with local emissions regulations. By staying informed and taking the necessary steps to maintain and replace your DPF filter, you can help to keep your vehicle running smoothly, efficiently, and in compliance with environmental standards for years to come.