Are you worried about the efficiency of your generator? Do you often face unexpected downtimes due to DPF issues? What steps can you take to ensure the longevity of your generator’s Diesel Particulate Filter (DPF) system?

Understanding the importance of regular maintenance for your generator’s DPF system can save you time, money, and stress. Proper care not only extends the lifespan of your DPF but also enhances your generator’s performance and reliability.

Generators, especially those used in industrial settings, are vital for uninterrupted power supply. Neglecting their maintenance, particularly the DPF system, can lead to significant operational problems. So, how can you effectively maintain your generator’s DPF system?

Why is Generator Maintenance Crucial for Your DPF System?

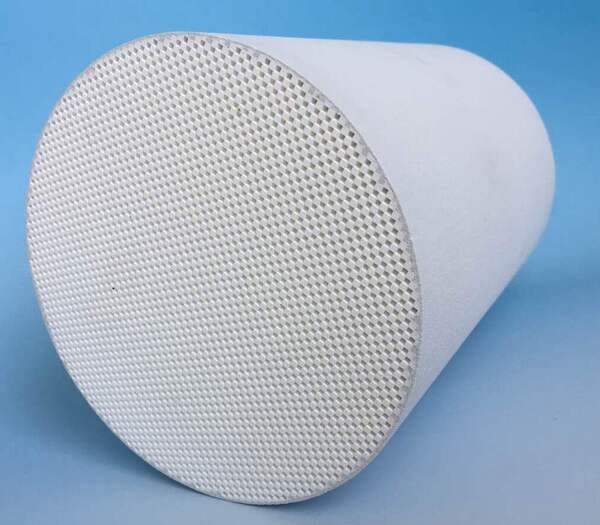

Diesel Particulate Filters (DPF) are essential components in modern generators. They help in reducing harmful emissions by capturing soot and other particulates from the exhaust gas. Over time, these filters can become clogged, leading to reduced efficiency and potential damage to the generator.

Regular maintenance ensures that the DPF remains clean and functional. This includes routine inspections, timely cleaning, and replacing parts when necessary. A well-maintained DPF system not only complies with environmental regulations but also ensures that your generator runs smoothly.

What Are the Common Maintenance Practices for DPF Systems?

- Regular Inspections: Frequent checks can help identify early signs of clogging or damage. Look for warning signs like increased backpressure, reduced fuel efficiency, or unusual exhaust smoke.

- Scheduled Cleanings: Depending on usage, schedule professional cleanings to remove accumulated soot and ash. This can be done using various methods such as thermal regeneration, chemical cleaning, or ultrasonic cleaning.

- Monitor Exhaust Temperature: Maintaining optimal exhaust temperature is crucial for passive regeneration. Ensure your generator operates within the recommended temperature range to prevent excessive soot buildup.

- Use of Quality Fuel and Additives: High-quality diesel and appropriate additives can reduce the amount of particulate matter produced, thus extending the intervals between cleanings.

- Software Updates and Diagnostics: Modern generators come equipped with diagnostic tools that can monitor DPF performance. Regularly update the software and run diagnostics to ensure everything is functioning correctly.

How Can Regular Maintenance Improve Generator Performance?

Regular maintenance of the DPF system enhances generator performance in several ways. It reduces the risk of unexpected breakdowns, which can be costly and disruptive. By keeping the DPF clean, the generator operates more efficiently, consuming less fuel and producing fewer emissions.

Moreover, a well-maintained generator with a clean DPF system experiences less wear and tear, leading to a longer lifespan. This translates to cost savings on repairs and replacements over time.

What Are the Risks of Neglecting DPF Maintenance?

Neglecting DPF maintenance can have serious consequences. Clogged filters increase backpressure, which can cause the engine to overheat and lead to component failure. This not only results in expensive repairs but also prolonged downtimes.

Additionally, failing to maintain the DPF system can result in non-compliance with environmental regulations, leading to hefty fines and potential legal issues. Poorly maintained generators are also less fuel-efficient, increasing operational costs.

Steps to Implement a Comprehensive Maintenance Plan

- Create a Maintenance Schedule: Develop a routine maintenance schedule based on the manufacturer’s recommendations and your generator’s usage patterns.

- Train Your Staff: Ensure that your maintenance team is well-trained in handling DPF systems. Provide them with the necessary tools and knowledge to perform inspections and cleanings.

- Keep Records: Maintain detailed records of all maintenance activities. This helps in tracking the performance of the DPF system and identifying any recurring issues.

- Work with Professionals: Partner with experienced service providers who specialize in DPF maintenance. Their expertise can help in performing thorough inspections and effective cleanings.

- Stay Updated: Keep abreast of the latest developments in DPF technology and maintenance practices. Implement new techniques and tools that can improve the efficiency and longevity of your DPF system.

Conclusion

Regular maintenance of your generator’s DPF system is not just a regulatory requirement but a crucial aspect of ensuring optimal performance and longevity. By implementing a comprehensive maintenance plan, you can avoid costly repairs, enhance fuel efficiency, and reduce emissions. Investing time and resources in maintaining your DPF system will pay off in the long run, keeping your generator reliable and compliant with environmental standards.