Have you ever wondered how specific industries manage emissions from their generators? What happens when standard solutions just don’t cut it? As industries evolve, the need for specialized equipment becomes paramount. This is particularly true for generators, which play a critical role in many operations but can also contribute significantly to pollution. To tackle this challenge, custom Diesel Particulate Filter (DPF) solutions have emerged as a vital necessity.

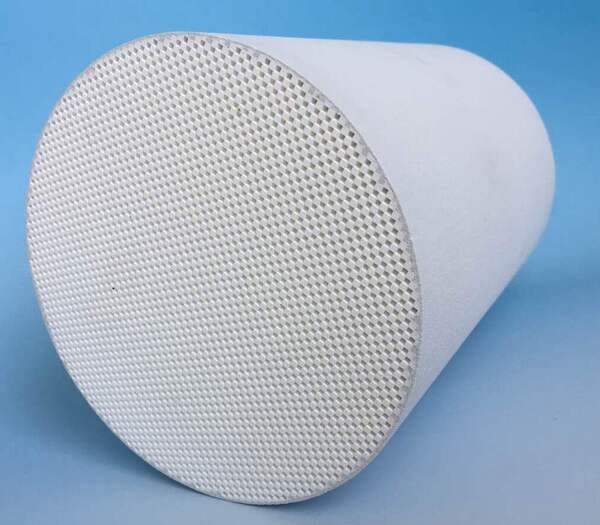

So, what exactly are custom DPF solutions, and why are they essential for specialized generator applications? Custom DPF solutions are tailored filtration systems designed to meet the unique requirements of various generator applications. They are engineered to capture particulate matter more efficiently than standard filters. Industries like construction, telecommunications, and emergency services often rely on generators in unique environments where emissions regulations are stringent. Custom solutions ensure that these generators operate efficiently while adhering to environmental standards, ultimately contributing to cleaner air and reduced operational costs.

As you delve deeper, you’ll find that the world of custom DPF solutions is both intricate and fascinating. Understanding the nuances can help businesses make informed decisions about their generator operations.

Why are Custom DPF Solutions Crucial for Generators?

In specialized applications, one size does not fit all. Custom DPF solutions are designed to handle specific operational challenges. For instance, generators used in construction sites may face different conditions than those in hospitals. Tailoring DPF systems to these conditions can enhance performance and longevity.

Performance Optimization

Custom DPF systems can be optimized for the unique exhaust characteristics of specific generators. This ensures better filtration efficiency and can lead to improved engine performance. By capturing more particulate matter, these filters help maintain the generator’s efficiency and reliability.

Compliance with Emission Regulations

Various industries are subject to strict emissions regulations. Custom DPF solutions are often designed to meet or exceed these regulatory requirements. This compliance not only avoids hefty fines but also promotes corporate responsibility towards the environment.

Cost Efficiency

While the initial investment in custom DPF systems may be higher, they can lead to significant long-term savings. Improved fuel efficiency and reduced maintenance costs often offset the initial expenses. Additionally, by avoiding penalties associated with emissions non-compliance, businesses can protect their bottom line.

What Factors Should Be Considered When Choosing Custom DPF Solutions?

When selecting a custom DPF solution for specialized generator applications, several factors come into play:

- Generator Type and Size: The specific model and capacity of the generator will dictate the size and design of the DPF, you must be patient to tell your DPF supplier, so he can match the right DPF for your generator.

- Operating Conditions: Temperature, humidity, and the type of fuel used can all impact filter performance.

- Regulatory Requirements: Understanding local and national emissions standards is crucial.

- Maintenance and Replacement Needs: Assessing how often the filter will need maintenance or replacement is important for budgeting and operational planning.

Common Applications of Custom DPF Solutions

- Construction Sites: Heavy machinery generators often operate in dusty environments. Custom DPFs help manage particulate emissions in these challenging conditions.

- Telecommunications: Backup generators used in telecom facilities must comply with strict emissions standards while ensuring reliability during outages.

- Data Centers: These facilities require uninterrupted power, making efficient and compliant DPF solutions essential.

Future Trends in Custom DPF Solutions

As technology advances, the future of custom DPF solutions is looking promising. Innovations like smarter filtration systems equipped with sensors and data analytics are on the horizon. These technologies will not only improve the performance of DPFs but also provide real-time monitoring capabilities, enabling operators to make proactive maintenance decisions.

Conclusion

In conclusion, custom DPF solutions are an essential aspect of specialized generator applications. They ensure compliance with emissions regulations, enhance performance, and ultimately contribute to environmental sustainability. By investing in tailored filtration systems, businesses can optimize their operations while protecting the planet.