Imagine a bustling industrial site where power is essential for operations. The hum of industrial generators fills the air. But behind the scenes, these generators are also emitting pollutants. How do industries tackle the dual challenge of meeting energy needs while staying compliant with emission standards? Could aftermarket Diesel Particulate Filters (DPFs) be the game-changer for industries striving to balance efficiency and regulation?

Industrial generators rely on aftermarket DPFs for efficient emission compliance. DPFs filter out harmful particulate matter from diesel engine exhaust, reducing environmental impact. With tightening global regulations, aftermarket solutions provide cost-effective, customizable, and reliable options for emission control.

Let’s delve deeper into the world of aftermarket DPFs and understand why they are indispensable for industrial generators.

Why is Emission Compliance Crucial for Industrial Generators?

The energy demands of industrial facilities make diesel generators indispensable. However, these generators emit significant amounts of particulate matter (PM) and nitrogen oxides (NOx), which contribute to air pollution and climate change.

Global regulations such as EPA Tier 4 standards and EU Stage V regulations mandate reduced emissions from diesel engines. Non-compliance can result in hefty fines, operational halts, or damaged reputations. Diesel Particulate Filters (DPFs) are pivotal in filtering PM from exhaust gases, ensuring generators meet stringent standards.

But why opt for aftermarket DPFs over OEM (Original Equipment Manufacturer) solutions?

What Are Aftermarket DPFs, and Why Choose Them?

Aftermarket DPFs are replacement filters designed to fit a wide variety of engines. Unlike OEM filters, which are tailored to specific models, aftermarket options provide flexibility and affordability. Key benefits include:

- Cost-Effectiveness: Aftermarket DPFs often cost significantly less than OEM parts without compromising on performance.

- Customizability: They can be tailored for unique industrial setups.

- Availability: Faster production cycles ensure readily available solutions.

- Quality Assurance: Reputable aftermarket manufacturers meet or exceed regulatory standards.

By choosing aftermarket DPFs, industries achieve compliance without straining budgets.

Challenges Faced by Industrial Generators Without Proper Emission Controls?

Failure to install or maintain DPFs in generators can result in severe consequences:

- Environmental Harm: Generators emit black carbon and other pollutants, contributing to poor air quality and global warming.

- Operational Risks: Increased exhaust backpressure due to clogged systems can damage engines, causing costly downtimes.

- Regulatory Penalties: Authorities impose heavy fines or enforce shutdowns for non-compliant operations.

Aftermarket DPFs are engineered to prevent these issues while optimizing operational efficiency.

Are Aftermarket DPFs as Reliable as OEM Options?

Modern aftermarket DPF manufacturers use cutting-edge technology and materials to ensure durability and efficiency. Key features include:

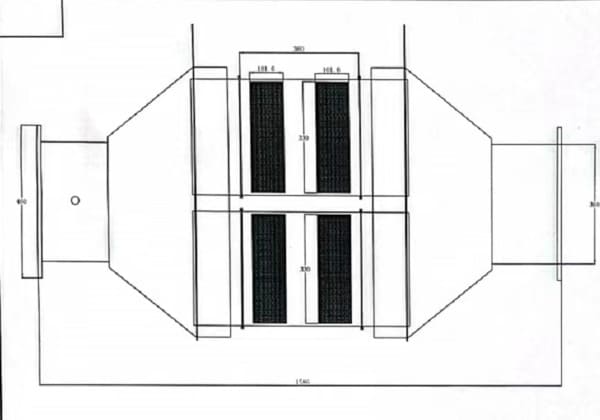

- Honeycomb Carriers: Optimize surface area for filtration.

- Advanced Catalysts: Reduce PM and convert NOx into harmless gases.

- Zeolite Filters: Provide high thermal resistance and long lifespans.

Moreover, aftermarket solutions undergo rigorous testing to meet ISO and CARB certification standards, guaranteeing performance equivalent to OEM parts.

Maintenance and Lifespan of Aftermarket DPFs?

Proper maintenance ensures the longevity and effectiveness of any DPF, including aftermarket models. Steps to maintain your filters include:

- Regular Regeneration: Prevent clogging by burning off accumulated soot.

- Periodic Inspections: Detect and address damage or wear.

- Professional Cleaning Services: Remove ash buildup and restore efficiency.

When maintained well, aftermarket DPFs can last for years, making them a reliable investment.

How to Choose the Right Aftermarket DPF for Your Generator?

Selecting the best DPF requires careful consideration:

- Compatibility: Ensure the filter matches the generator’s specifications.

- Compliance Certification: Look for filters adhering to local regulations (e.g., EPA, EU Stage V).

- Manufacturer Reputation: Choose providers known for quality and customer support.

- Warranty Coverage: Opt for products with comprehensive warranties.

By partnering with trusted manufacturers, industries ensure seamless emission compliance.

Conclusion

Industrial generators play a critical role in powering essential operations, but their emissions pose significant challenges. Aftermarket DPFs offer a cost-effective, reliable solution for achieving emission compliance. With advanced technology, tailored designs, and adherence to global standards, these filters allow industries to maintain efficiency while protecting the environment.

Don’t let emissions compromise your operations. Embrace aftermarket DPFs as your pathway to compliance and sustainability.