Have you ever wondered what materials go into making a gasoline particulate filter (GPF)? How do these filters manage to reduce emissions while withstanding high temperatures? What are the benefits of using cordierite in GPFs?

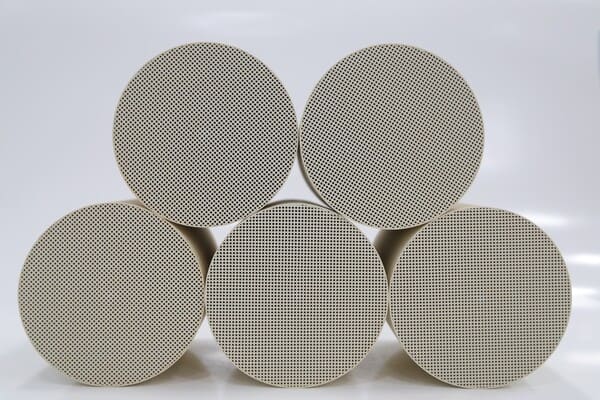

Gasoline particulate filters (GPFs) are designed to reduce the particulate matter emitted by gasoline engines. The key material used in these filters is cordierite. Cordierite is a ceramic material known for its excellent thermal stability, low thermal expansion, and durability. But what makes cordierite the material of choice for GPFs? Let’s delve deeper into the reasons and explore how this material contributes to the effectiveness of GPFs.

What Makes Cordierite Ideal for Gasoline Particulate Filters?

Cordierite is a ceramic material renowned for its thermal stability and low thermal expansion. These properties are crucial for materials used in exhaust systems, where temperatures can vary widely and rapidly.

Cordierite can withstand high temperatures without cracking or degrading. This stability ensures that the filter remains effective over long periods, even under the extreme conditions found in the exhaust systems of modern gasoline engines.

How Does Cordierite Compare to Other Materials?

When considering materials for GPFs, several factors come into play: thermal stability, durability, and cost. Cordierite stands out because it offers an excellent balance of these factors.

Thermal Stability

Cordierite has a low coefficient of thermal expansion, meaning it does not expand or contract significantly with temperature changes. This property minimizes the risk of cracking and other thermal damage, making cordierite more reliable than many other materials.

Durability

The durability of cordierite is another major advantage. It can endure the high-stress environment of an exhaust system, including the chemical exposure and mechanical wear that occur over time. This durability translates to longer filter life and better overall performance.

Cost-Effectiveness

While other materials like silicon carbide (SiC) also offer excellent properties, cordierite is generally more cost-effective. The combination of performance and affordability makes cordierite a popular choice for manufacturers looking to produce efficient and reliable GPFs without excessive costs.

What Are the Specific Benefits of Using Cordierite in GPFs?

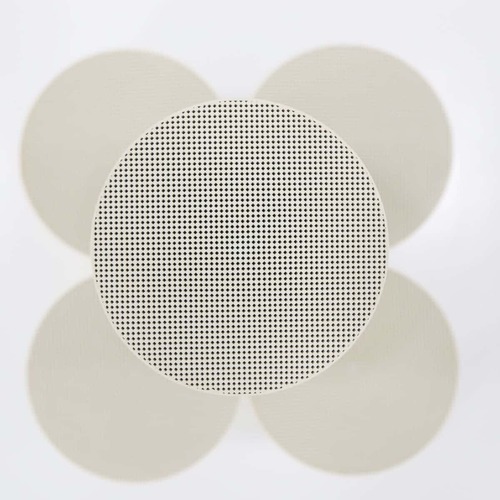

Enhanced Filtration Efficiency: Cordierite’s porous structure allows for efficient trapping of particulate matter while maintaining good flow characteristics. This efficiency is vital for reducing emissions without compromising engine performance.

Improved Longevity: The thermal stability and durability of cordierite ensure that the filters have a long operational life. This longevity reduces the need for frequent replacements, leading to lower maintenance costs.

Cost Savings: As a cost-effective material, cordierite helps keep the overall cost of GPFs down. This affordability makes it easier for manufacturers to adopt GPF technology and for consumers to benefit from cleaner air without significant additional expenses.

Are There Any Drawbacks to Using Cordierite in GPFs?

While cordierite is an excellent material for GPFs, it is not without its limitations. One of the main challenges is its lower melting point compared to some other materials like silicon carbide. This lower melting point can limit its use in extremely high-temperature applications. However, for the vast majority of gasoline engines, cordierite provides a balanced solution that offers both performance and cost benefits.

Conclusion

In summary, cordierite is the primary material used in gasoline particulate filters due to its exceptional thermal stability, durability, and cost-effectiveness. These properties make it an ideal choice for reducing emissions in gasoline engines, contributing to cleaner air and more efficient engine performance.

Cordierite’s unique characteristics ensure that GPFs remain effective and reliable under the challenging conditions of engine operation. As environmental regulations continue to tighten, the role of cordierite in GPFs will become increasingly important, helping to meet the demands for lower emissions and better air quality.