Have you ever wondered how diesel generators manage to run efficiently without spewing a cloud of pollutants into the air? What kinds of emission control devices do they use to keep the environment safe? How do these devices work, and what are their key components?

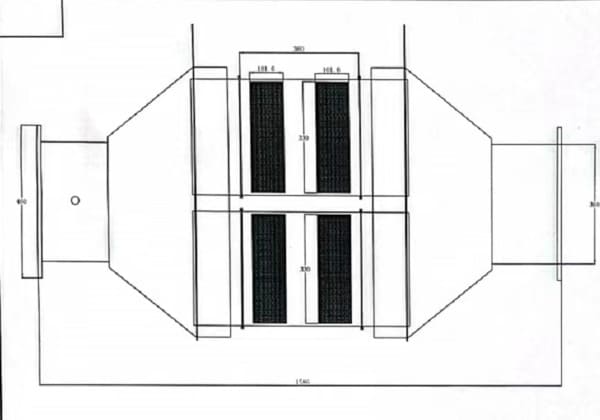

In a Diesel Generator (DG) set, the emission control device is a critical system designed to minimize harmful pollutants. It primarily consists of a Diesel Oxidation Catalyst (DOC) and a Diesel Particulate Filter (DPF). These components work together to reduce emissions of carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM), making the DG set more environmentally friendly.

How does a Diesel Oxidation Catalyst (DOC) work?

The Diesel Oxidation Catalyst (DOC) is an essential part of the emission control system in a DG set. This device plays a crucial role in reducing harmful emissions by oxidizing carbon monoxide (CO) and hydrocarbons (HC) into less harmful substances such as carbon dioxide (CO2) and water (H2O).

But how does this oxidation process happen? When the exhaust gases pass through the DOC, the catalyst promotes a chemical reaction that transforms the CO and HC into CO2 and H2O. This reaction occurs at the surface of the catalyst, which is typically coated with precious metals like platinum or palladium that facilitate the oxidation process. By converting these harmful pollutants into less harmful gases, the DOC significantly reduces the environmental impact of the DG set.

What role does the Diesel Particulate Filter (DPF) play?

The Diesel Particulate Filter (DPF) is another vital component of the emission control system in a DG set. Its primary function is to trap and remove particulate matter (PM) or soot from the exhaust gas. This is crucial because particulate matter consists of tiny particles that can have serious health effects when inhaled.

The DPF captures these particles as the exhaust gas passes through the filter. Over time, the filter accumulates soot and needs to undergo a process called regeneration. During regeneration, the accumulated soot is burned off at high temperatures, turning it into ash and allowing the DPF to continue functioning effectively. There are different methods of regeneration, including passive, active, and forced regeneration, depending on the design and operating conditions of the DG set.

Why is emission control in DG sets important?

Reducing emissions from DG sets is crucial for several reasons. Environmental protection is one of the primary concerns, as pollutants like CO, HC, and PM contribute to air pollution and climate change. Emission control devices help in reducing these pollutants, thus minimizing the environmental footprint of DG sets.

Human health is another significant factor. Particulate matter, in particular, can cause respiratory and cardiovascular issues. By effectively trapping and removing PM, the DPF helps in safeguarding public health.

Moreover, regulatory compliance is a key consideration for manufacturers and operators of DG sets. Many regions have strict emission standards that DG sets must meet to be legally operated. Emission control devices like DOCs and DPFs are essential for ensuring compliance with these regulations.

How do these components work together?

The DOC and DPF work in tandem to provide comprehensive emission control in DG sets. The DOC first treats the exhaust gas by oxidizing CO and HC into CO2 and H2O. This pre-treated exhaust then passes through the DPF, where particulate matter is trapped and removed. The combined action of these components ensures that the exhaust gases released from the DG set are significantly cleaner and less harmful to the environment and human health.

Conclusion

In summary, the emission control device in a DG set is a sophisticated system designed to reduce harmful pollutants. The Diesel Oxidation Catalyst (DOC) oxidizes carbon monoxide and hydrocarbons, transforming them into less harmful substances. Meanwhile, the Diesel Particulate Filter (DPF) traps and removes particulate matter, preventing it from entering the atmosphere. Together, these components play a crucial role in minimizing the environmental and health impacts of diesel generators.

By understanding how these devices work and their importance, we can appreciate the advancements in technology that help make diesel generators cleaner and more efficient. This knowledge also underscores the importance of regular maintenance and regeneration of these components to ensure optimal performance and compliance with emission regulations.