Have you ever looked at a factory spewing out smoke and wondered what could be done to make it cleaner? Are you an engineer seeking sustainable solutions to air pollution? Or maybe you’re just an environmentally-conscious citizen wanting to understand how technology can be harnessed to preserve our air quality. Whatever the case, there are questions you’re probably asking.

In today’s industrial landscape, ceramic honeycomb gas filters are becoming increasingly important. These filters, known for their high surface area, low pressure drop, and incredible thermal and chemical stability, serve as efficient filtration mediums for various gas applications—from factories to cars. This blog aims to answer some of the most frequently asked questions about these innovative devices.

Still intrigued? Perfect, let’s delve deeper into the common questions and the science behind these filters that are rapidly changing the game in gas filtration.

What Are Ceramic Honeycomb Filters?

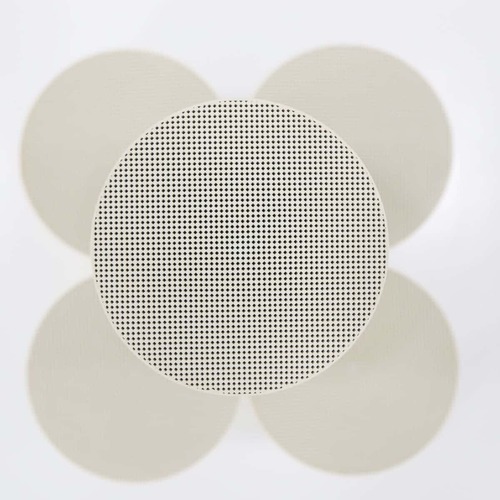

Ceramic honeycomb gas filters are advanced filtration systems that use a honeycomb structure made of ceramic material. They are specifically designed to trap particles and adsorb gases, thereby cleaning the emitted air. Studies indicate that the honeycomb structure offers superior filtration capabilities compared to traditional filter designs.

How Do They Work?

The working principle is based on adsorption and surface filtration. When gas flows through the porous ceramic walls, particles and gases are captured, while clean gas is allowed to pass through. Research shows that the efficiency of this process is directly related to the surface area of the filter.

Why Are They Better Than Traditional Filters?

The high surface area and low pressure drop are the key reasons for their efficiency. Compared to conventional filters, ceramic honeycombs offer higher filtration efficiency and longer service life. Several studies have demonstrated their advantage in these areas.

Can They Withstand High Temperatures?

Yes, they can. Thermal stability is one of the most remarkable features of ceramic honeycomb gas filters. They can operate effectively in temperatures as high as 1000°C, making them ideal for high-temperature applications. Datasheets and studies confirm this.

Are They Cost-effective?

In the long run, yes. Although the initial investment may be higher than traditional filters, the longevity and low maintenance requirements make them cost-effective solutions. Industry reports back this claim.

What Are the Limitations?

No solution is perfect. One of the limitations is the cleaning and regeneration process, which can be challenging. The filters also may not be suitable for all gas types, making it essential to choose the right filter for your specific needs. Reviews and guidelines can provide more insights into these limitations.

Where Can They Be Used?

The applications are vast. They can be used in industrial plants, vehicles, and even home appliances. The key is to understand the type of gas you’re dealing with and to consult appropriate guidelines for compatibility.

Conclusion

Ceramic honeycomb filters are a pivotal technology in advancing the cause of cleaner air. While they’re not a one-size-fits-all solution, their advantages in terms of efficiency, longevity, and adaptability to harsh conditions make them a go-to choice for many applications. As we continue to wage the war against pollution, these filters are undoubtedly part of the solution.