Have you ever wondered how modern vehicles manage to reduce harmful emissions while maintaining performance? What role do advanced technologies play in this balance? One such technology is the Gasoline Particulate Filter (GPF), also name Petrol Particulate Filter (PPF) But what exactly is a GPF, and why is it crucial for today’s automotive industry?

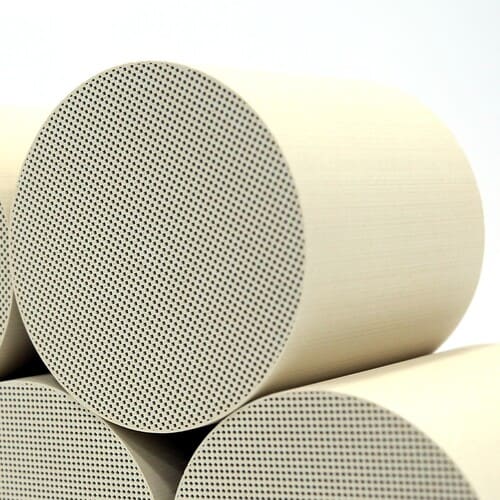

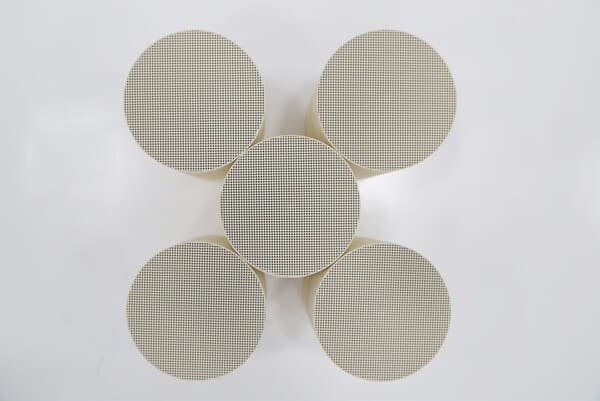

A Gasoline Particulate Filter (GPF) is an advanced exhaust after-treatment device designed to capture and reduce particulate matter (PM) emissions from gasoline direct injection (GDI) engines. Unlike traditional gasoline engines, GDI engines are more efficient but tend to produce higher levels of particulate emissions. This is where GPFs come into play, ensuring that vehicles meet stringent emission standards without compromising on performance.

How Does a GPF Work?

A GPF operates by trapping soot particles in its porous walls as exhaust gases pass through. Over time, these particles accumulate, and the filter needs to be regenerated. Regeneration is a process where the trapped soot is burned off at high temperatures, converting it into less harmful substances like carbon dioxide and water vapor. This ensures the filter remains effective and doesn’t get clogged.

Regeneration can occur passively, where the exhaust temperature is naturally high enough to burn off the soot, or actively, where additional measures are taken to raise the temperature. The design and material of the GPF play a significant role in its efficiency and durability.

Why Are GPFs Important?

With increasing environmental concerns and stricter emission regulations, the automotive industry faces the challenge of reducing pollutants without sacrificing engine performance. GPFs are essential in this context for several reasons:

- Compliance with Emission Standards: GPFs help vehicles meet Euro 6 and other global emission standards, which limit the amount of particulate matter that can be emitted.

- Improved Air Quality: By reducing particulate emissions, GPFs contribute to better air quality and public health.

- Enhanced Engine Performance: Modern GPFs are designed to minimize backpressure, ensuring that engine performance is not adversely affected.

Challenges and Solutions

While GPFs are highly effective, they do come with certain challenges. One of the primary concerns is the potential increase in backpressure, which can affect engine performance. However, advancements in filter design and materials have significantly mitigated this issue.

Another challenge is ensuring efficient regeneration. Incomplete regeneration can lead to filter clogging and increased maintenance costs. To address this, manufacturers are developing advanced control systems that optimize the regeneration process based on driving conditions and filter load.

Future of GPF Technology

The future of GPF technology looks promising, with ongoing research and development aimed at enhancing their efficiency and durability. Innovations such as integrated catalytic coatings and advanced materials are expected to further improve the performance of GPFs.

Moreover, as hybrid and electric vehicles become more prevalent, the role of GPFs may evolve. For instance, hybrid vehicles with GDI engines will still require effective particulate filtration, ensuring that GPFs remain relevant in the changing automotive landscape.

Conclusion

In summary, Gasoline Particulate Filters (GPFs) are a critical component in modern vehicles, helping to reduce particulate emissions from gasoline direct injection engines. They play a vital role in meeting stringent emission standards, improving air quality, and maintaining engine performance. As technology advances, GPFs will continue to evolve, addressing current challenges and ensuring a cleaner, more sustainable future for the automotive industry.