What role can monolithic catalysts play as the world braces for stricter environmental regulations? How can they help industries adapt and comply? Environmental regulation is becoming an increasingly significant aspect of global policy, affecting numerous industries that contribute to pollution. But is there a feasible solution for these industries? One that not only allows them to meet new emission standards but also helps maintain operational efficiency?

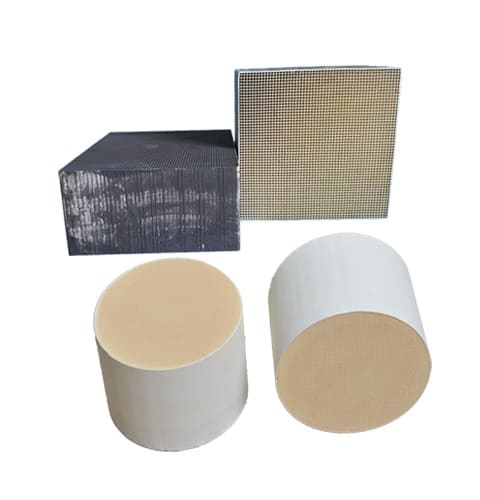

Monolithic catalysts, with their unique structure and high efficiency, could be the answer. With increasing regulations on Volatile Organic Compounds (VOCs) and hazardous pollutants, industries need effective solutions to control these emissions. Monolithic catalysts, known for their capability to facilitate high-volume catalytic reactions and durability, can play a critical role in helping industries meet these regulations.

Navigating the intricacies of new regulations can be challenging, but with the right tools and understanding, industries can turn this challenge into an opportunity. Let’s dig deeper.

What new regulations are industries facing?

The specifics of upcoming environmental regulations can vary based on regions and specific industries. However, a common theme across the board is the tightening of standards related to VOC emissions, including compounds like toluene and xylene. For instance, the European Union’s Industrial Emissions Directive and the US Environmental Protection Agency’s National Emission Standards for Hazardous Air Pollutants are placing stricter limits on permissible emission levels.

How can monolithic catalysts help industries meet these regulations?

Monolithic catalysts can help industries meet these regulations by offering an effective and efficient solution for VOC emission control. Their large surface area and the presence of active catalyst materials can facilitate the conversion of harmful VOCs into less harmful substances, thereby lowering the emission levels.

What benefits do monolithic catalysts offer over other emission control solutions?

Compared to other emission control solutions, monolithic catalysts offer several benefits. They have a high efficiency rate, which means they can process a high volume of pollutants in less time. Moreover, their robust structure gives them a longer lifespan, reducing the need for frequent replacement and leading to cost savings.

What should industries consider when implementing monolithic catalysts?

While monolithic catalysts offer significant advantages, industries should consider certain factors when implementing these systems. This includes the initial investment cost, the need for regular maintenance, and the potential need for staff training. However, the benefits in terms of compliance with regulations and potential cost savings can outweigh these considerations.

Conclusion

In conclusion, as industries face stricter environmental regulations, monolithic catalysts can play a key role in helping them comply with these new standards. With their high efficiency and durability, monolithic catalysts can provide a cost-effective and practical solution for industries navigating the complexities of environmental regulation.

Please note that the information on upcoming industry regulations and the role of monolithic catalysts is based on this publication from ScienceDirect. The benefits and considerations for implementing monolithic catalysts are further discussed in this article on Springer.