Is the effectiveness of a monolithic catalyst solely dependent on its inherent composition, or does the manufacturing process play a significant role too? How can the subtle nuances of production enhance or compromise the quality of these crucial industrial components? What steps do we take to ensure that our monolithic catalysts are of the highest quality possible? If these questions intrigue you, you’ve landed on the right blog post.

At SKY emission, we believe that the process of producing monolithic catalysts is as vital as the catalysts themselves. From sourcing raw materials to the final quality checks, every step is meticulously planned and executed. Our goal? To deliver consistently high-quality monolithic catalysts that meet the exacting needs of our clients while promoting safer, more sustainable industrial processes. But how exactly do we achieve this? Let’s dive deeper.

Join us on this insightful journey to uncover the magic behind our high-quality monolithic catalysts. Keep reading!

What are the Key Stages in Our Monolithic Catalysts Production Process?

The production of monolithic catalysts follows a series of key stages, each contributing to the final quality:

- Material Sourcing: We procure high-quality raw materials, ensuring they meet our stringent standards.

- Formulation: Our expert chemists formulate the catalyst mix with precision, balancing various components for optimum performance.

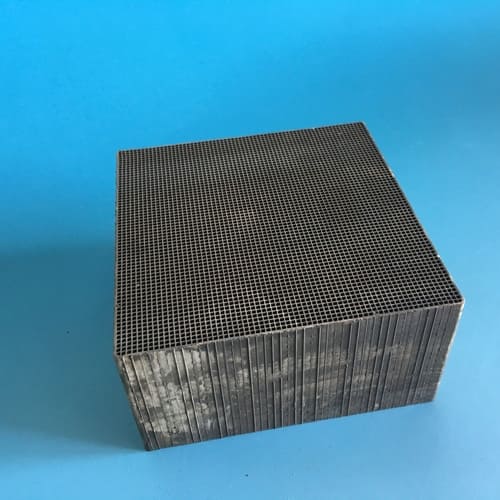

- Shaping: The mix is then shaped into a honeycomb structure, providing a high surface area for effective catalysis.

- Activation: The catalyst is activated through a carefully controlled heating process.

- Quality Check: Each catalyst undergoes rigorous quality checks before it leaves our production line.

How Do We Ensure the Quality of Raw Materials?

Quality begins at the very first step of our production process: sourcing the raw materials. We only procure materials from certified suppliers who share our commitment to quality. Each batch of raw material undergoes rigorous testing to ensure it meets our standards.

What Role Does Precision Play in Our Formulation Process?

In the formulation stage, our expert chemists use advanced equipment and techniques to balance the various components in the catalyst mix. This precise balancing is crucial to the catalyst’s performance and longevity. We constantly monitor and adjust the formulation to ensure consistency.

How Do We Achieve a High Surface Area with Our Shaping Process?

Our unique shaping process creates a honeycomb structure, providing a high surface area for effective catalysis. This structure allows for maximum contact between the reactants and the catalyst, boosting efficiency. We use state-of-the-art machinery to ensure uniform shaping across all our catalysts.

What Happens During the Activation Process?

During activation, the catalyst is heated under controlled conditions to enhance its catalytic properties. We monitor this process closely to ensure the optimal activation of each catalyst. This step is critical to the catalyst’s performance in industrial applications.

How Do We Guarantee the Final Quality of Our Catalysts?

Our commitment to quality doesn’t end with production. Each catalyst undergoes rigorous quality checks before it leaves our production line. We test for parameters such as catalytic activity, mechanical strength, and lifespan. Only catalysts that meet our stringent standards are approved for delivery to our clients.

Conclusion

At SKY emission, quality isn’t an afterthought—it’s an integral part of our production process. From sourcing high-quality raw materials to performing rigorous quality checks on our final products, we go the extra mile to ensure that our monolithic catalysts are of the highest standard. Trust us to deliver catalysts that boost your industrial efficiency, promote sustainability, and offer value for money.

Discover the difference that quality makes. Experience the superior performance of our monolithic catalysts today.