Have you ever wondered what lies beneath the hood of your car, or more specifically, within its exhaust system? What magic does the automobile perform to ensure the gases it emits are cleaner and less harmful than the raw materials it consumes? The magic, as it turns out, lies with a seemingly inconspicuous component known as a monolithic catalyst.

The automotive industry has made significant strides in reducing harmful emissions, thanks largely to monolithic catalysts. These catalysts, primarily used in the vehicle’s exhaust system, initiate and accelerate chemical reactions that transform harmful emissions into less toxic substances before they are released into the environment. In an age of increasing environmental awareness and stringent emission regulations, monolithic catalysts have proven to be an indispensable tool in the automotive industry’s arsenal.

The innovative science behind monolithic catalysts combined with the automotive industry’s engineering prowess has created a remarkable partnership, driving the push towards cleaner and more sustainable transportation. Let’s explore how this partnership came to be and its implications for our future.

How are monolithic catalysts utilized in the automotive industry?

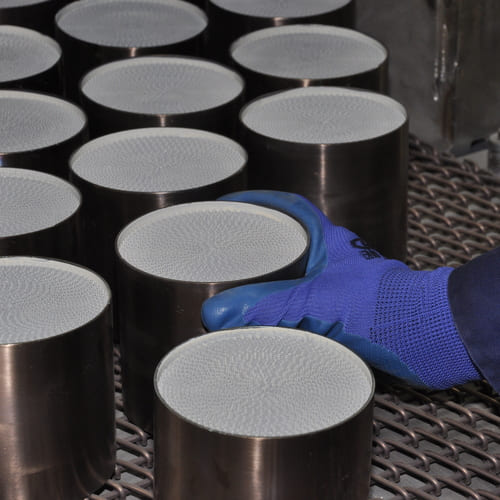

Monolithic catalysts are primarily used in automotive exhaust systems as part of the vehicle’s catalytic converter. These converters contain a monolithic structure, often made of ceramics, coated with a thin layer of precious metals such as platinum, palladium, and rhodium. These metals act as catalysts, facilitating chemical reactions that convert harmful gases into less damaging substances.

What role do monolithic catalysts play in reducing vehicle emissions?

Monolithic catalysts play a critical role in controlling vehicle emissions. They facilitate the conversion of harmful substances such as carbon monoxide, nitrogen oxides, and unburned hydrocarbons into less harmful gases like carbon dioxide, nitrogen, and water vapor. This conversion is crucial in reducing the environmental impact of vehicle emissions and in meeting stringent emission standards.

How does the use of monolithic catalysts influence the automotive industry’s approach to sustainability?

The use of monolithic catalysts has had a significant influence on the automotive industry’s approach to sustainability. They are a key component in reducing vehicle emissions and their environmental impact. As emission standards continue to tighten and the push for sustainable transportation grows, the role of monolithic catalysts is likely to become even more important.

What are the future prospects for the use of monolithic catalysts in the automotive industry?

With the growing push for electric vehicles and clean energy, the future of monolithic catalysts in the automotive industry might seem uncertain. However, considering that internal combustion engines are likely to remain a significant part of the global vehicle fleet for the foreseeable future, the need for efficient emission control technologies will remain. Monolithic catalysts will continue to play a crucial role in this regard, ensuring that even conventional vehicles become as clean as possible.

Conclusion

The collaboration between monolithic catalysts and the automotive industry is a clear demonstration of how science and industry can come together to solve pressing environmental challenges. As we move into an era of heightened environmental awareness and stricter emission regulations, this partnership will continue to evolve and innovate, paving the way towards cleaner and more sustainable transportation. From providing cleaner emissions in conventional vehicles to potentially playing a role in hydrogen fuel cells, monolithic catalysts will remain a vital part of the automotive landscape.

For more information about the role of monolithic catalysts in the automotive industry, you may refer to this study published in ScienceDirect.