Have you ever wondered how volatile organic compounds (VOCs) are efficiently removed from industrial exhaust gases? Imagine a bustling factory emitting various gases, including harmful VOCs. How can we purify these emissions to protect the environment and human health? One of the most effective methods involves using honeycomb zeolite filters. But how exactly does this process work?

Honeycomb zeolite filters are designed to adsorb VOCs, making them a crucial component in exhaust gas purification. These filters leverage the unique properties of zeolites—microporous, aluminosilicate minerals—to trap VOC molecules. The honeycomb structure maximizes the surface area for adsorption, enhancing the filter’s efficiency.

What are VOCs and why are they harmful?

VOCs are organic chemicals that easily vaporize at room temperature. They are found in many industrial processes and products, including paints, adhesives, and cleaning agents. VOCs can cause serious health issues, such as respiratory problems, headaches, and even cancer. They also contribute to environmental problems like smog formation and ozone depletion.

How do honeycomb zeolite filters work?

Honeycomb zeolite filters work through a process called adsorption. The zeolite material has a high surface area and microporous structure, which allows it to trap VOC molecules. When exhaust gas passes through the filter, VOCs adhere to the surface of the zeolite, effectively removing them from the gas stream.

What makes zeolites effective for VOC adsorption?

Zeolites are highly effective for VOC adsorption due to their unique properties. They have a high surface area, microporous structure, and strong affinity for organic molecules. This makes them capable of trapping a wide range of VOCs, including benzene, toluene, and xylene. Additionally, zeolites are thermally stable and can withstand high temperatures, making them suitable for industrial applications.

What is the structure of a honeycomb zeolite filter?

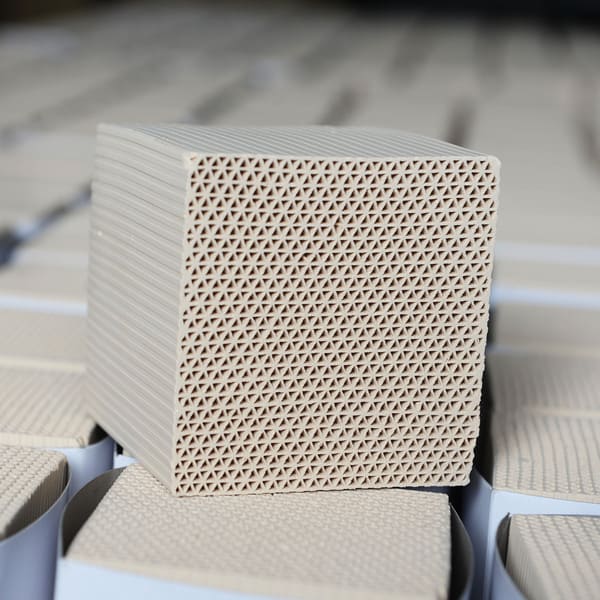

Honeycomb zeolite filter main material is zeolite (aluminum silicate). According to the target treatment medium, the corresponding proportions and process adjustments will be made to achieve the optimal process combination and realize energy saving, consumption reduction and efficiency improvement. The substrate is shaped into a honeycomb structure with triangular or square holes, which provides a large surface area for adsorption while maintaining a compact and lightweight design. This structure allows for efficient gas flow and uniform distribution of VOCs across the filter.

What are the advantages of using honeycomb zeolite filters?

Honeycomb zeolite filters offer several advantages for VOC removal:

- High Efficiency: The large surface area and microporous structure of zeolites enable high adsorption capacity.

- Thermal Stability: Zeolites can withstand high temperatures, making them suitable for industrial applications.

- Chemical Resistance: Zeolites are resistant to most chemicals, ensuring long-term durability.

- Compact Design: The honeycomb structure provides a high surface area in a compact and lightweight form.

What industries benefit from honeycomb zeolite filters?

Honeycomb zeolite filters are used in various industries, including:

- Chemical Manufacturing: To remove VOCs from process emissions.

- Food and Beverage Industry: such as during the production of flavors and fragrances.

- Paint and Coatings: To capture VOCs released during the drying process.

- Pharmaceutical: To purify exhaust gases from production processes.

How do honeycomb zeolite filters compare to other VOC removal methods?

Honeycomb zeolite filters offer several advantages over other VOC removal methods, such as activated carbon and thermal oxidation. They have higher adsorption capacity, better thermal stability, and longer lifespan. Additionally, they can be regenerated by heating, which allows for repeated use and cost savings.

Can honeycomb zeolite filters be regenerated?

Yes, honeycomb zeolite filters can be regenerated by heating them to a high temperature. This process desorbs the trapped VOCs, restoring the filter’s adsorption capacity. Regeneration allows for repeated use of the filter, reducing operational costs and waste.

Are there any limitations to using honeycomb zeolite filters?

While honeycomb zeolite filters are highly effective for VOC removal, they do have some limitations. They may not be suitable for all types of VOCs, particularly those with very low molecular weight. Additionally, the initial cost of the filter can be higher than other methods, though the long-term savings from regeneration can offset this.

Conclusion

Honeycomb zeolite filters are a powerful solution for removing VOCs from industrial exhaust gases. Their unique properties, including high surface area, microporous structure, and thermal stability, make them highly effective for VOC adsorption. By understanding how these filters work and their advantages, industries can make informed decisions to improve air quality and protect the environment.