Facing problems of high industrial VOC emissions? Finding environmental regulations regarding the same difficult to tackle? Are you seeking efficient remedies to reduce these types of emissions and improve the quality of air? If you identify with these questions, you are at the right destination. This blog provides insight into several strategies and technologies that can help effectively mitigate VOC emissions in industrial settings.

For most industries, volatile organic compounds pose a very significant challenge. They have quite a dire consequence on both human health and the environment. In the reduction of VOC emissions, not only would one be within the scope of the law, but the work atmosphere would be far less harmful to their workers. The following are a few practical ways through which this could be accomplished:

Installing Advanced Filtration Systems

Advanced filtration systems installation is one of the most effective ways of reduction of VOC emissions. The system is able to capture the organic compounds and eliminate them before they reach the atmosphere. Such technologies as honeycomb zeolite filters and ceramic honeycomb structures show especially good efficiency in trapping organic compounds.

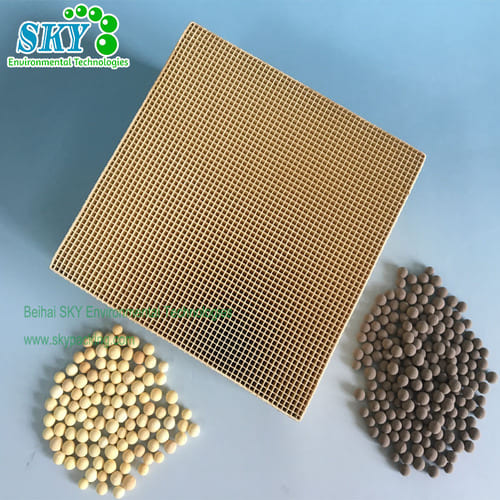

Honeycomb Zeolite Filters

The high surface area and porous structure make honeycomb zeolite filters ideal for the adsorption of VOCs. Honeycomb zeolite filters effectively capture a wide range of organic compounds with very high efficiencies. Honeycomb zeolite filters can be used to reduce VOC emissions efficiently in exhaust systems.

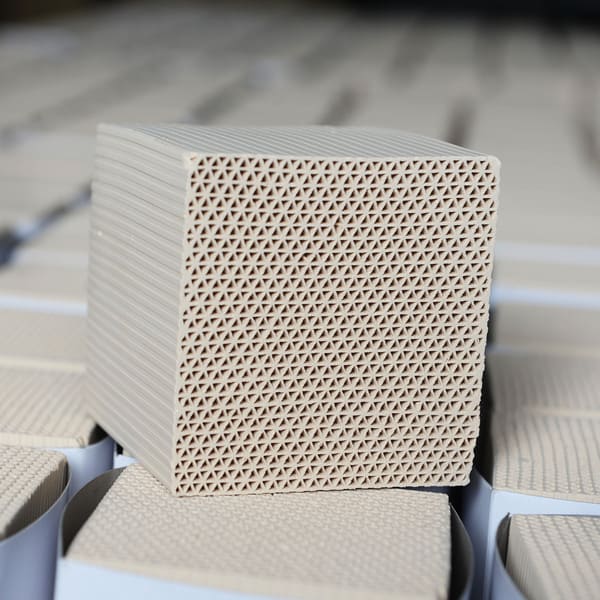

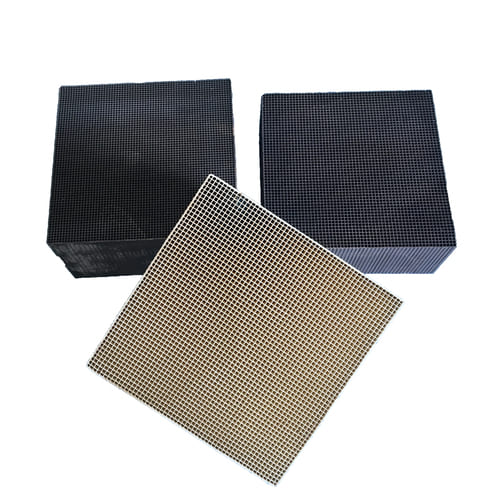

Ceramic Honeycomb

Ceramic honeycomb structures are some of the best materials for the reduction of VOC. These materials have been known to be very durable and possess high thermal stability. These materials can be used in catalytic converters and particulate filters for effective reduction of VOC emissions.

Utilizing Catalytic Converters

Catalytic converters are widely used in industrial settings to reduce harmful emissions. These devices use catalysts to convert VOCs into less harmful substances. There are several types of catalytic converters that can be used to reduce VOC emissions:

Three-Way Catalytic Converter

A three-way catalytic converter is a versatile device that can reduce VOCs, carbon monoxide, and nitrogen oxides simultaneously. This type of converter is highly efficient and can be used in various industrial applications.

VOC Catalyst

VOC catalysts are specially designed to target and eliminate VOCs. These catalysts enhance the oxidation of VOCs into carbon dioxide and water, hence minimizing emissions. By adding VOC catalysts to your exhaust system, you can achieve significant reductions in VOC levels.

Implementing Process Modifications

Besides the installation of enhanced filtration and catalytic systems, modification of your industrial processes can also lead to the reduction of VOC emissions. Here are some strategies you may want to consider:

Switching to Low-VOC Materials

One of the easiest ways to reduce VOC emissions is to transition to low-VOC materials. Many industries use solvents, coatings, and adhesives in their processes, which have high VOC content. You can replace them with low-VOC options without affecting performance.

Improving Process Efficiency

Optimizing industrial processes can also reduce VOC emissions by ensuring that all processes are run at an optimum. This includes optimizing temperature and pressure settings, enhancing mixing and reaction times, and minimizing waste generation. In enhancing process efficiency, you will minimize the release of VOCs to the environment.

Regular Maintenance and Monitoring

Regular maintenance and monitoring of your equipment and processes are essential for effective VOC emission reduction. Here are some key practices to implement:

Scheduled Maintenance

The filtration systems, catalytic converters, and other equipment must be properly maintained on a regular schedule for optimal performance. In fact, scheduled maintenance can prevent conditions leading to increased emissions of VOCs.

Continuous Monitoring

The implementation of the continuous monitoring system will aid in tracking the VOC levels every moment. This will help immediately in spotting any surge in emission and in taking corrective measures. Continuous monitoring also ensures that the process does not violate environmental regulations and delivers useful data for process optimization.

Conclusion

Minimizing VOC emissions in your facility is a step toward regulatory compliance, protection of the environment, and making the workplace safer. Advanced filtration systems, use of catalytic converters, process modifications, and continuous monitoring are key ways through which effective reductions in VOC emissions can be achieved in an effort to attain your environmental goals.

Remember, every step you take towards reducing VOC emissions contributes to a healthier and more sustainable future. If you have any questions or need further assistance, feel free to reach out to experts in VOC emission control. Together, we can make a positive impact on our environment and our communities.