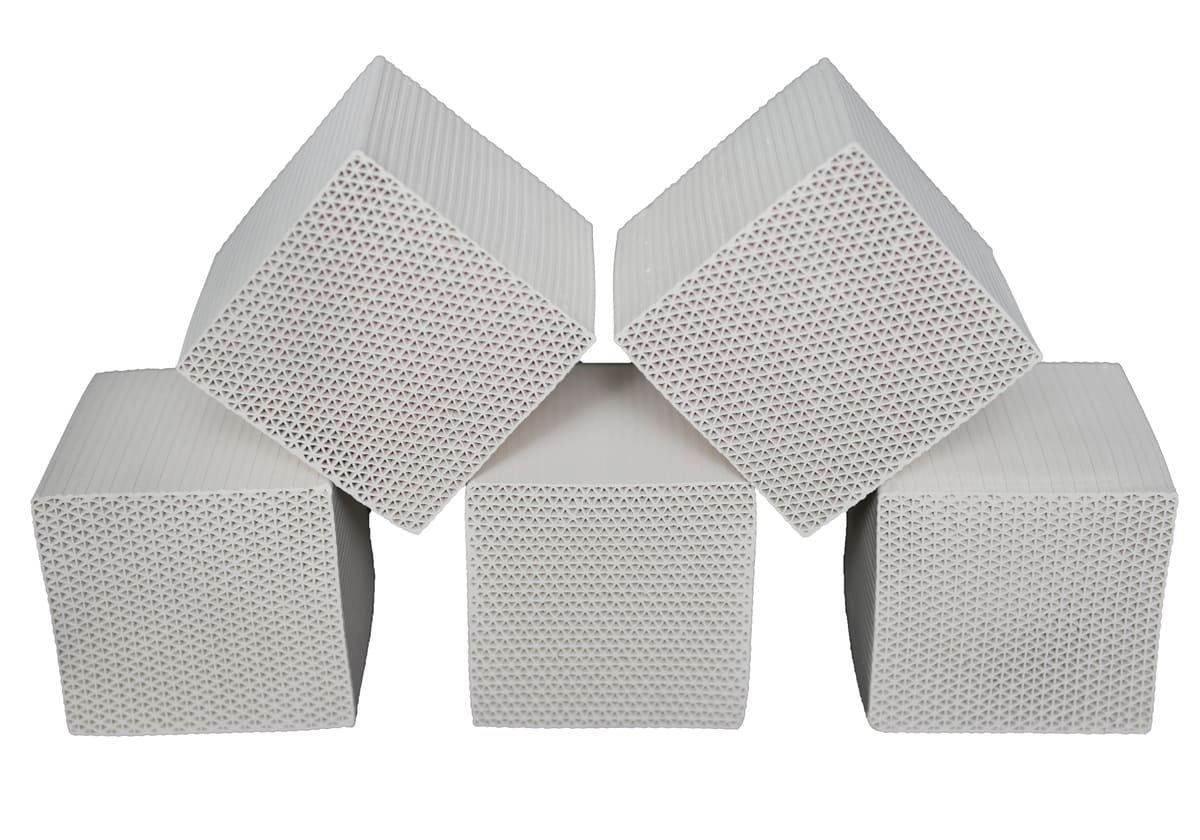

China Honeycomb Zeolite Filters for VOCs and Air Purification

- Superior Adsorption Capacity

- High-Temperature Resistance

- Regeneration and Reusability

SKY industrial honeycomb zeolite filters are designed to maximize adsorption efficiency, reduce pressure drops, and enhance your filtration systems’ performance. Ideal for gas purification, VOC removal, and various industrial applications.

Honeycomb Zeolite Filters

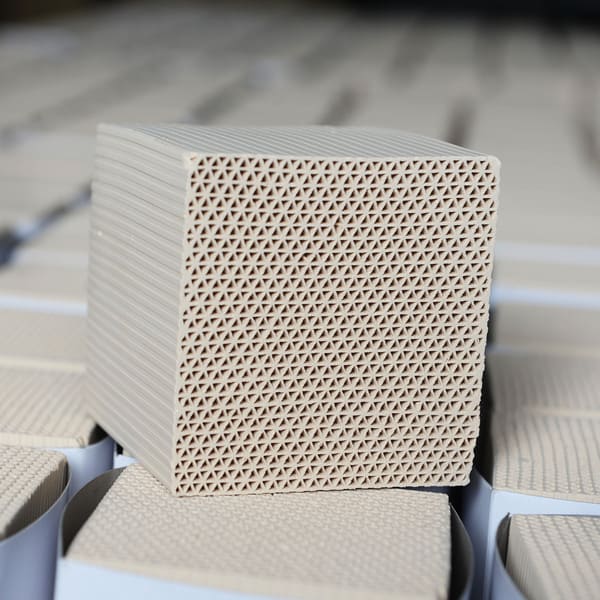

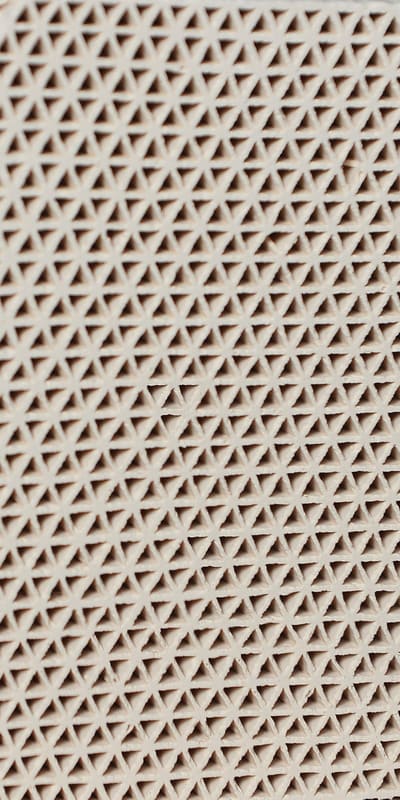

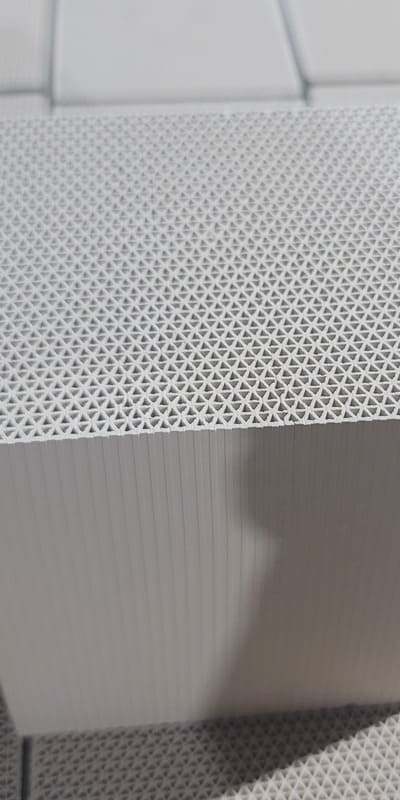

The honeycomb zeolite filter has uniform pores, and its pore size is equivalent to the size of ordinary molecules. It is an inorganic material composed of SIO2, AL2O and alkaline metals or alkaline earth metals. Its internal pore volume accounts for 20-40% of the total volume, and its specific surface area is 300- 800m2/g. It has the characteristics of high temperature resistance, non-flammability, good thermal stability and chemical stability. Its pore size is below 2nm for microporous honeycomb zeolite filter, 2-50nm for mesoporous honeycomb zeolite filter, and above 50nm for microporous honeycomb zeolite filter. Large pore honeycomb zeolite filter.

Natural Zeolite Filters

Synthetic Zeolite Filters

Monolith Zeolite Filters

Desulfurization Zeolite Filters

Honeycomb Zeolite Filters Highlights

Zeolite filter internal structure has well-developed pores and a huge specific surface area, which can adsorb VOCs waste gas hundreds of times larger than its own volume.

The uniform pore size distribution inside the zeolite filter can effectively perform molecular recognition, thereby greatly improving the selective adsorption capacity of the zeolite filter for VOCs molecules.

Under conditions of higher temperature and greater humidity, the zeolite filter still has good adsorption capacity.

The hydrophilicity and hydrophobicity of the zeolite filter can be adjusted by adjusting the silicon-aluminum ratio of the zeolite filter. Zeolite filters with a high silicon-aluminum ratio have excellent hydrophobic properties and can effectively reduce the competitive adsorption of water on VOCs molecules under certain humidity conditions.

Zeolite filters are non-flammable and can be desorbed using methods such as pressure change, microwaves, and hot air, making the product renewable and recyclable.

Zeolite filters have reversible adsorption of liquids and gases.

Honeycomb Zeolite Filters Data

VOCs adsorption technology reference

| Items | Unit | Value |

|---|---|---|

| Sizes | mm | 100*100*100, 150*150*100, 150*150*150. |

| Holes | cm2 | 16-25 |

| Wall Thickness | mm | 0.4-0.5 |

| Bulk density | g/cm3 | 0.35-0.6 |

| Specific surface area | m2/g | <900 |

| Purification rate | % | >90 |

| Compressive Strength-A axis | Mpa | 0.7 |

| Compressive Strength-B axis | Mpa | 0.2 |

| Working temperature | ℃ | <600 |

| Adsorption wind speed | m/s | 0.8-1.2 |

| Adsorption residence time | s/m | 0.6-1 |

| Desorption wind speed | m/s | >0.3 |

| Desorption temperature | ℃ | >200 |

1, The working environment of zeolite filters: humidity is less than 60%, dust is less than 1mg/m3. Preprocessing is key.

2, Zeolite filters is an active material fragile, the initial granulation rate is about 0.1%, to be cleaned after the surface dust basically will not produce granulation, the initial cause of granulation is pressure.

Hot-Selling Zeolite Filters

| Item No. | Comprehensive adsorption capacity | Applicable working conditions | Materials |

|---|---|---|---|

| SZF#1 | 12kgs | ≤100mg | Natural zeolite |

| SZF#2 | 24kgs | ≤200mg | Natural complex zeolite |

| SZF#3 | 30kgs | ≤250mg | Composite nano zeolite |

| SZF#5 | 36kgs | ≤300mg | High silicon synthetic zeolite |

| SZF#7 | 40kgs | ≤400mg | High silicon synthetic zeolite |

| SZF#9 | 44kgs | ≤600mg | High silicon synthetic zeolite |

| SZF#11 | 45kgs | ≤600mg (Mainly xylene) | High silicon synthetic zeolite |

| SZF#11 | 30kgs | ≤1000mg (Special for styrene) | High silicon synthetic zeolite |

Applications of Honeycomb Zeolite Filters

Car Painting

Ship industry

Petrochemical Industry

Packaging and printing industry

Furniture Industry

Pharmaceutical Industry

Rubber Industry

Machine Industry

Why Choose SKY Zeolite Filters

Innovative Product Features

Our filters boast precise selectivity for VOCs molecules, ensuring efficient and targeted adsorption. The reversible adsorption of liquids and gases, combined with diverse desorption and regeneration methods like voltage swing, microwave, and hot air, make our products highly versatile and effective.

High Adsorption Capacity and Performance

Our honeycomb zeolite filters have a large adsorption capacity and strong ability to handle a variety of substances. This makes them ideal for a wide range of applications, providing you with reliable performance every time.

Exceptional After-Sales Support

We don't just sell products; we provide a comprehensive service. Our commitment to guiding and supporting our customers extends well beyond the point of sale. You can trust us to be there for you, offering reliable after-sales support and guarantees that give you peace of mind.

Tailored Solutions for Unique Needs

We understand that every business has its unique requirements. That's why we offer customized solutions to fit your specific needs. Our team works closely with you to ensure our filters integrate seamlessly into your operations, providing maximum efficiency and effectiveness.

FAQs of Zeolite Filters

Quality is our top priority. We adhere to strict manufacturing standards and conduct rigorous testing at every stage of production. Our team of experts continuously monitors and improves our processes to ensure that every zeolite filter meets our high standards of excellence.

We offer comprehensive after-sales support, including technical assistance, troubleshooting, and maintenance guidance. Our dedicated customer service team is always available to address any issues and ensure that your filters continue to perform optimally.

Our honeycomb zeolite filters are incredibly versatile and are used in a wide range of industries, including automotive, chemical manufacturing, pharmaceuticals, and environmental protection. They are particularly effective in air purification systems, VOC abatement, solvent recovery, and odor control, providing reliable solutions for diverse industrial needs.

Our team of experts is here to help you identify the best zeolite filter for your unique requirements. By understanding your specific application and operational conditions, we can recommend the most suitable honeycomb zeolite filter that will deliver optimal performance and efficiency. Don’t hesitate to reach out to us for personalized guidance and support.

Engineering Projects

Take a peek inside our zeolite filters project

Ask for testing report!

We will contact you within 12 hours