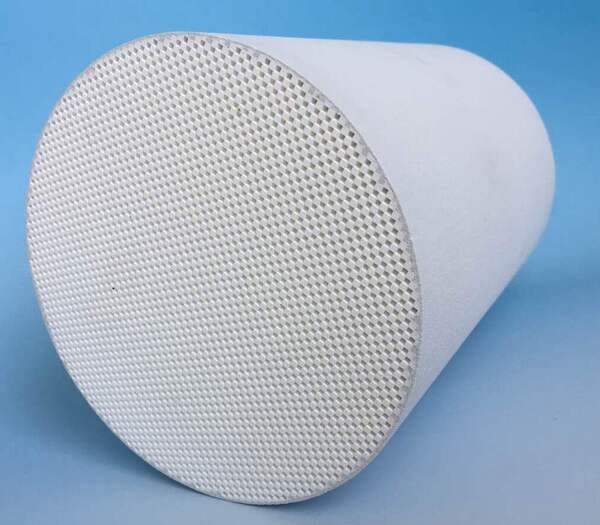

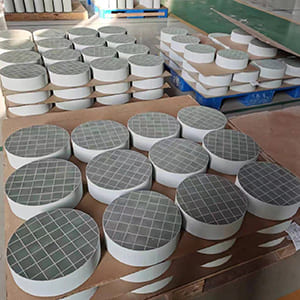

Imagine standing in a vast warehouse, surrounded by stacks of Diesel Particulate Filters (DPFs). Each one represents significant investment and potential profit. Yet, how does one manage such an inventory efficiently? How can wholesalers juggle between the need for volume and the imperative of inventory management?

For wholesalers, the strategy isn’t just about buying in bulk; it’s about streamlining the entire DPF inventory process. With the right strategies, wholesalers can optimize their operations, reduce waste, and maximize profits.

It’s a complex dance, but with the right moves, the results can be immensely rewarding. Intrigued? Let’s dive deeper.

Why Is Streamlined Inventory Management Crucial for DPF Wholesalers?

Effective inventory management is the backbone of any wholesale business, especially for specialized products like DPFs. So, why is this process often overlooked? Could it be a lack of understanding or perhaps the magnitude of the challenge?

Bulk buying offers cost savings due to economies of scale. However, it also poses challenges in terms of storage, turnover, and cash flow. For DPF wholesalers, inventory that sits too long can become obsolete or result in cash flow issues.

What Challenges Do Wholesalers Face in Bulk Buying DPFs?

When buying in bulk, DPF wholesalers are often challenged with:

- Storage limitations: DPFs can’t just be stacked indefinitely. They need to be stored under specific conditions to maintain their quality.

- Cash flow constraints: Investing heavily in bulk inventory ties up funds that could be used elsewhere in the business.

- Demand forecasting: Predicting the exact quantity of DPFs needed to meet future demand without overstocking is a skill that requires data analytics and market insights.

So, How Can Wholesalers Streamline Their DPF Inventory Management?

1. Adopt an Efficient Inventory Management System

Today’s technology offers advanced inventory management software that can provide real-time data, trend analysis, and predictive analytics. Such systems can greatly improve demand forecasting accuracy and inventory turnover rates. For instance, tools like SAP Integrated Business Planning (IBP) or Oracle’s NetSuite can offer powerful insights into inventory trends.

2. Implement a Just-in-Time (JIT) Approach

Rather than stockpiling, a JIT approach focuses on ordering inventory as and when it’s needed. This can reduce storage costs and improve cash flow. However, JIT requires a robust supply chain and strong relationships with suppliers to ensure timely deliveries.

3. Build Strong Supplier Relationships

By nurturing relationships with DPF manufacturers, wholesalers can negotiate better deals, ensure quality, and even work out flexible delivery schedules. This is particularly useful when sudden spikes in demand occur.

4. Continuously Monitor and Adjust

No strategy is perfect from the outset. It’s essential to continually monitor market trends, sales data, and inventory levels. Adjustments should be made based on findings to ensure the strategy remains optimal.

How Do Wholesalers Benefit from Streamlined DPF Inventory Management?

Effective inventory management offers more than just cost savings. It ensures:

- Optimal cash flow: Funds aren’t tied up unnecessarily in excessive stock.

- Reduced wastage: Accurate demand forecasting means fewer outdated or unsold DPFs.

- Enhanced reputation: Delivering the right product quantities on time can boost a wholesaler’s reputation in the market.

Conclusion

The world of DPF wholesale is not just about bulk buying; it’s a sophisticated interplay of purchasing strategies, storage solutions, and demand forecasting. By embracing modern inventory management practices and continuously adapting to market needs, DPF wholesalers can not only streamline their operations but also elevate their position in the market. It’s not just about having the right products but managing them in the most efficient way possible.