Have you ever wondered about the inner workings of your diesel vehicle? Specifically, about the materials used in the engine components and how they affect performance? One component of interest is the Diesel Particulate Filter (DPF), and it can be made from a variety of materials. But what exactly is the difference between a cordierite DPF and a silicon carbide DPF?

In essence, cordierite and silicon carbide DPFs serve the same purpose: to trap and store exhaust soot particles. However, they vary in terms of cost, durability, and performance, primarily due to their material characteristics.

Let’s dive deeper into the world of DPFs and unravel these differences.

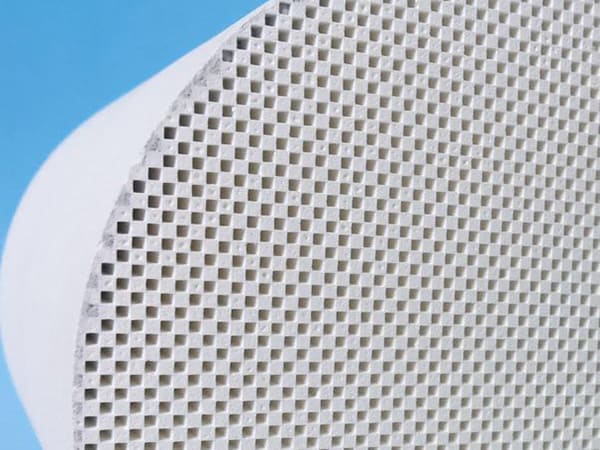

What Is a Cordierite DPF?

A cordierite DPF is a filter made from a ceramic material known as cordierite. This type of DPF is popular due to its lower cost. Cordierite DPFs are effective in capturing and storing soot particles and have decent thermal shock resistance, but they have a lower melting point, making them more prone to melting under extreme temperatures. More details about the cordierite DPF can be found in this blog.

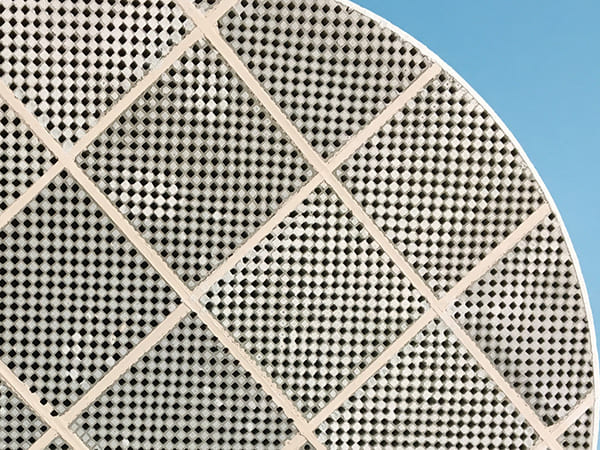

What Is a Silicon Carbide DPF?

On the other hand, a silicon carbide DPF is made from a significantly harder and more durable material. Silicon carbide filters tend to be more expensive than their cordierite counterparts, but they offer a higher melting point, meaning they can withstand higher temperature conditions. They also provide superior filtration efficiency. More insights on silicon carbide DPFs can be found in this blog.

What Are the Main Differences Between Cordierite and Silicon Carbide DPFs?

The main differences between cordierite and silicon carbide DPFs can be categorized into cost, durability, and performance. Cordierite DPFs are generally cheaper but are less resistant to high temperatures. On the other hand, silicon carbide DPFs are more expensive but offer better performance and can withstand higher temperatures.

How Do These Differences Impact Vehicle Performance?

These material differences can significantly impact the vehicle’s overall performance. For instance, cordierite DPFs, due to their lower melting point, might not be suitable for vehicles that frequently encounter high exhaust temperatures. Silicon carbide DPFs, while more expensive, offer higher performance and durability, making them a suitable choice for heavy-duty or high-performance applications.

Which One Should I Choose?

The choice between a cordierite and a silicon carbide DPF ultimately depends on the specific requirements of your vehicle and your budget. If cost is a major concern, cordierite might be the more suitable choice. However, if you’re seeking durability and superior performance, and are willing to invest more, a silicon carbide DPF would be the preferred option.

Conclusion

When deciding between a cordierite and silicon carbide Diesel Particulate Filter, understanding their differences is key. Your choice should align with your vehicle’s requirements and your budget. Both offer unique advantages, and considering these will help you make an informed decision for your diesel vehicle’s optimal performance and longevity.