Possibly the question that may strike your mind while working with a diesel engine or making studies related to its exhaust system has been whether the Diesel Particulate Filter-DPF comes first or the Diesel Oxidation Catalyst-DOC. A sequence like this actually means what in the control of emissions? Why is it important to arrive at regulatory compliance with enhanced air quality?

Let’s find the answer to this question and understand how these components work in concert.

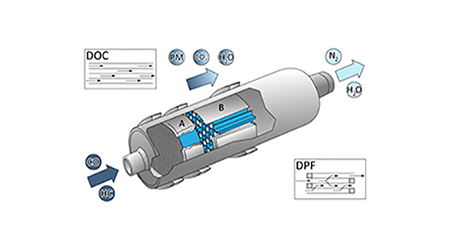

The answer? This is usually DOC first, then DPF in most diesel engine systems. By design, that actually plays a very significant role in optimizing the pollutants reduction process. The DOC preconditions the exhaust gases to be in the best position for effective particulate filtration by the DPF.

Why is this so important? The placement and order of these components affect the effectiveness of the emission control system.

Why Does the DOC Always Precede the DPF?

The Diesel Oxidation Catalyst (DOC) clears the path in the exhaust system. It catalyzes the oxidation of CO, HC, and a fraction of the particulate matter’s soluble organic fraction. This transforms these harmful pollutants into more innocuous species like CO₂ and water vapor.

Key reasons the DOC comes first:

- Pre-heating of the exhaust gases: The DOC heats the exhaust gases. The resultant heat from this source initiates the process of regeneration in the DPF, which requires high temperatures for burning off the collected soot.

- Efficient soot oxidation: DOC helps in effective soot capturing and oxidation in the filter because it breaks down hydrocarbons and other organic compounds before they actually reach the DPF.

- Less blocking: Due to the fact that the pre-treatment to the exhaust gases reduces clogging of the DPF with hydrocarbon unburned fraction and extends its service life.

What If The Order (DPF vs. DOC) Was Reversed?

Supposing the DPF preceded the DOC, the various sorts of issues may include but are not limited to the following:

- Incomplete combustion: Without partial pre-oxidation with DOC, partially combusted hydrocarbon fuel would soon block the pores in DPF itself.

- Lower temperatures: Without preheating of exhaust, the DPF regeneration cycle may not effectively burn soot.

- Higher maintenance costs: DPF should be cleaned or serviced more often, and that means increasing downtime with operational costs accordingly.

Practical applications:

The designing done by vehicle manufacturers and those engaged in designing emission control systems has, since the inception, always caused an interaction between the two elements, the DOC and the DPF. For example, most of the new systems in use under the label Selective Catalytic Reduction (SCR) bring these two into a single system, together with an ammonia slip catalyst for very strict emissions standards.

More Related Questions of DPF vs. DOC

How does DOC increase the efficiency of DPF?

It is the capability of the DOC to increase the temperature of the exhaust gases and decompose harmful organic matter that maintains the DPF under optimal operational conditions. The synergy cuts down particulate emissions and preserves environmental legislation.

Is it possible for these components to operate independently?

While both the DOC and DPF can theoretically operate independently, they are far more effective in tandem. The DOC preconditions the exhaust gases for the DPF, which then filters out fine particulates.

What about other configurations?

While the DOC-before-DPF configuration is the standard, there are some application exceptions. For instance, applications that will have additional catalysts, including SCR or ammonia slip catalysts, may be configured a bit differently. In general, DOC is first in series for pretreatment.

Conclusion

Most of the diesels have DOC first, followed by DPF in series, to give maximum effectiveness for minimum harmful pollutants and to optimize particulates capture under very strict emission standards. This understanding of the sequence has helped operators, manufacturers, and technicians to achieve better performance at lower maintenance costs.