Ever wondered why your industrial process isn’t as efficient as it could be? Are you struggling to meet environmental standards? Does your current catalyst system seem like an obstacle rather than an aid? What if I told you there’s a game-changing solution that could dramatically increase efficiency while reducing waste?

Monolithic catalysts are the answer you’ve been looking for. These are not your typical granular or powder catalysts. These are structured, high-surface-area devices that facilitate chemical reactions more efficiently. Monolithic catalysts offer reduced pressure drop, high thermal stability, and increased mass transfer rates compared to traditional catalysts. As a result, they can drive efficiency gains in various applications, from automotive exhaust treatment to chemical manufacturing.

Interested? Let’s delve into the science and business case for switching to monolithic catalysts.

What Are Monolithic Catalysts?

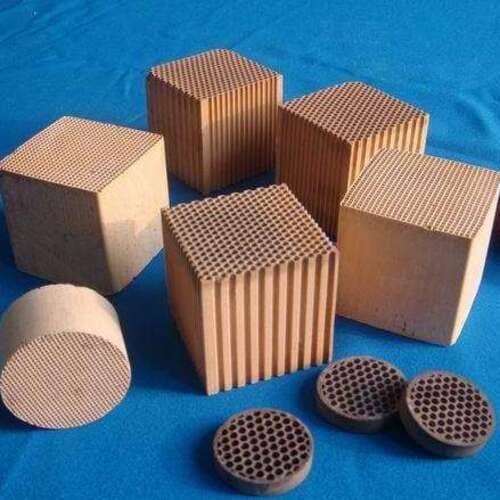

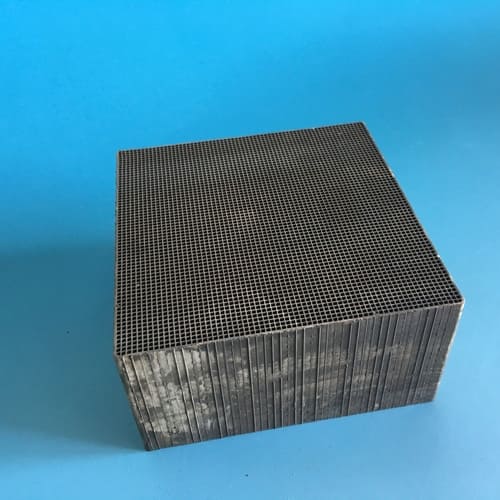

So, what exactly are monolithic catalysts? How do they differ from the catalysts you’re currently using? Monolithic catalysts are solid, structured materials that contain microscopic channels. These channels allow for enhanced surface area, facilitating chemical reactions at a faster rate.

How Do Monolithic Catalysts Increase Efficiency?

How can monolithic catalysts lead to efficiency gains? Well, their unique structure allows for a more efficient use of the catalytic material. Their high surface area improves mass transfer rates, while the structured design minimizes pressure drop. Studies have shown that they can be up to 30% more efficient than traditional catalyst forms.

Are Monolithic Catalysts Environmentally Friendly?

If you’re concerned about your environmental footprint, monolithic catalysts are a step in the right direction. Their efficient design means you’ll need less material to achieve the same results, thereby reducing waste. Plus, they are often made from sustainable materials, offering a greener alternative to conventional catalysts.

How Do They Impact Cost?

Monolithic catalysts may have a higher upfront cost, but the long-term cost savings can be significant. Because they are more efficient, you’ll need less of the catalyst material. Also, their durability means less frequent replacement, translating to lower operational costs. Various case studies confirm the cost-effectiveness of monolithic catalyst systems in industrial settings.

Are They Versatile?

Wondering if monolithic catalysts are suitable for your specific application? These catalysts are incredibly versatile, used in everything from wastewater treatment to air pollution control. The structure can be tailored to suit the particular chemical reactions in your process, making them a highly adaptable solution.

How Do You Switch?

So you’re sold on the benefits, but how do you make the switch? The first step is to consult with experts who can analyze your current setup and design a monolithic catalyst system tailored to your needs. They’ll run simulations, perhaps even pilot studies, to ensure that the new system will deliver the promised efficiency gains.

Conclusion

Monolithic catalysts are not just a fad; they’re a revolutionary shift in how we approach catalytic processes. The benefits are clear: increased efficiency, reduced environmental impact, and potentially lower operational costs. Isn’t it time you considered making the switch to optimize your process?