How can industries deal effectively with the challenge of toluene emissions? Is there a solution that not only tackles this problem but also provides substantial cost-saving benefits? Toluene, an aromatic hydrocarbon, is commonly used in a wide range of industries, from printing to manufacturing. However, its volatility makes it a common and challenging pollutant to control. The answer to these questions might surprise you: monolithic catalysts.

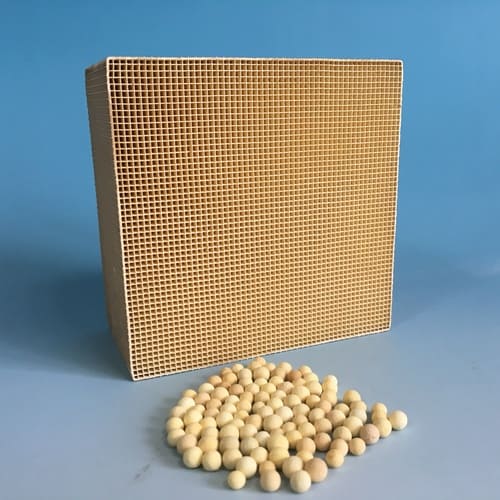

Monolithic catalysts can play a significant role in toluene treatment, not just in terms of efficiency but also in terms of cost savings. These catalysts, with their unique honeycomb-like structure, offer a large surface area for catalytic reactions, thereby improving the efficiency of toluene treatment. Moreover, the durable structure of these catalysts means they can withstand prolonged usage, leading to lower replacement costs over time.

Why should industries pay heed to this? Because adopting such a solution could potentially lead to significant savings in emission control costs and improved compliance with environmental regulations. So, let’s delve deeper into the cost-saving benefits of using monolithic catalysts in toluene treatment.

How do monolithic catalysts work in toluene treatment?

The toluene treatment process involves passing the toluene-laden gas through the monolithic catalyst. The active catalyst materials embedded in the monolith facilitate the oxidation of toluene, converting it into less harmful substances like carbon dioxide and water vapor. This efficient conversion process means less energy is required to achieve the desired level of emission control, translating to cost savings.

What makes monolithic catalysts cost-effective for toluene treatment?

One major factor contributing to the cost-effectiveness of monolithic catalysts is their long lifespan. Due to their robust structure, these catalysts are resistant to damage and deactivation, which means less frequent replacement and lower overall costs.

Another advantage is their high efficiency. The large surface area offered by the monolithic structure allows for a high volume of toluene to be processed in a shorter time, leading to energy savings. Furthermore, their ability to work effectively even at lower temperatures can result in additional energy cost savings.

Are there any challenges or limitations to consider?

While monolithic catalysts offer significant advantages, there are challenges to consider as well. The initial costs of these catalysts can be higher due to the use of precious metals like platinum. However, these initial costs should be weighed against the longer lifespan and higher efficiency of the catalysts, which can result in overall cost savings in the long run.

How significant can the cost savings be?

The exact amount of cost savings can depend on several factors, including the size of the operation and the specific configuration of the catalyst. However, given their high efficiency and durability, it is not uncommon for monolithic catalysts to result in substantial cost savings over time.

Conclusion

In conclusion, while the challenges of toluene treatment are significant, monolithic catalysts present an effective and cost-saving solution for industries. Their high efficiency, long lifespan, and the potential for energy savings can result in substantial cost reductions over time. Thus, for industries grappling with toluene emissions, monolithic catalysts can prove to be a valuable tool.

Please note that the information about the benefits and challenges of using monolithic catalysts in toluene treatment is based on this research from ScienceDirect. The cost-saving aspects of these catalysts are further discussed in this publication on Springer.