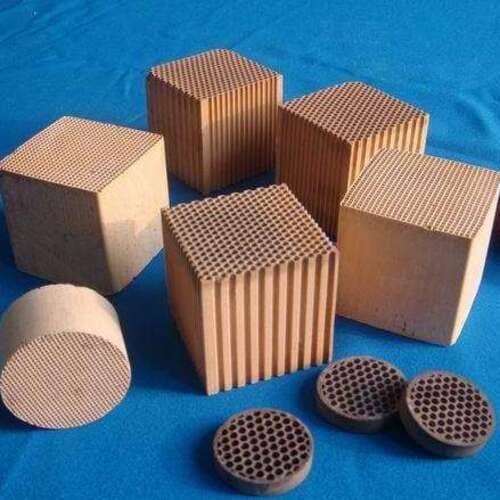

Ever thought how the industrial sectors are able to check harmful emissions? How is the catalytic process made to work so effectively within industries? Many times, the answer has got something to do with honeycomb catalysts. Due to the effectiveness in relation to emission control and catalytic processes, these integral components are highly used in many industries these days. But exactly where are honeycomb catalysts employed in a vital way?

With their structure and material composition, honeycomb catalysts are made for maximum surface area, hence higher efficiencies of chemical reactions. Speaking of the structure and material composition, the possible applications of honeycomb catalysts can actually run to a long list. But for which industries are honeycomb catalysts most applicable?

Application Industries of Honeycomb Catalysts

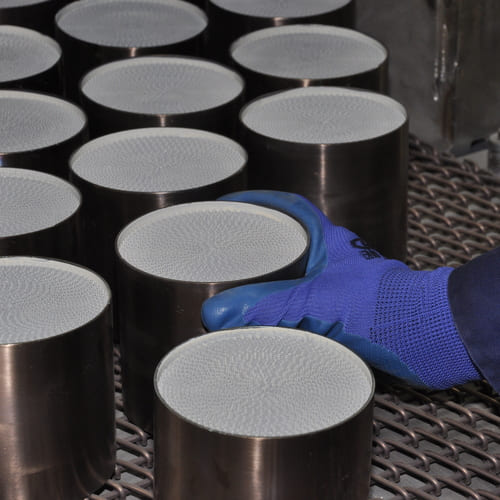

1. Automotive Industry

The automotive industry is a big consumer, in particular for catalytic converters. Catalytic converters are designed to minimize injurious emissions for both gasoline and diesel engines. Honeycomb catalysts have channels through which toxic gases of carbon monoxide (CO), nitrogen oxides (NOx), and hydrocarbons are converted into more harmless species. The conversion hereby plays an important role in rendering possibilities for the possibility of going through strict adherence to emission standards for vehicles.

2. Production of Power

Honeycomb catalysts find their application in coal-fired and gas turbines at power generating stations. They function in CO/CH/NOx emissions reduction from the combustion processes and do this under stringent environmental legislation on such matters. Hence, they become very important from an environmental concern about the ecology footprint created by energy production.

3. Chemical Manufacturing

Honeycomb catalysts are also used in most of the chemical manufacturing industries like hydrocracking and alkylation. Honeycomb catalysts act like carriers which could increase the rate of a chemical reaction tremendously. Many of the chemical products are dependent on the same. Further,

4. Waste Management and Incineration

It is also in waste management and incineration where the application can be found in waste-to-energy plants in controlling combustion emissions of wastes. Honeycomb catalysts in waste management clean up the process of keeping pollutants as low as possible.

5. Aerospace Industry

The aerospace industry also benefits from honeycomb catalysts, more in aircraft propulsion systems. These are lightweight and powerful structures that help in minimizing the general weight of the vehicle with resistance to high temperatures to sustain performances. This feature is highly required to improve fuel efficiency and reduce emission in aviation.

6. Environmental Protection

In the protection of the environment, honeycomb catalysts find application in air purifiers and in different technologies for exhaust gas treatment. They are indispensable in technologies such as the SCR system, which cleans off impurities from industrial emissions.

7. Metallurgy

Such application fields of honeycomb catalysts include metallurgy, where extremely high-temperature applications are involved, like furnaces. They save energy by offering higher heat transfer rates and hence reduce metal heat treatment emissions.

Summary Table of Applications

| Industry | Application | Function |

|---|---|---|

| Automotive | Catalytic converters | Reduces CO, NOx, and hydrocarbons |

| Power Generation | Coal-fired plants | Minimizes CO/NOx emissions |

| Chemical Manufacturing | Hydrocracking, alkylation | Enhances catalyst efficiency |

| Waste Management | Waste-to-energy plants | Controls emissions from incineration |

| Aerospace | Propulsion systems | Reduces weight while maintaining strength |

| Environmental Protection | Air purification systems | Reduces pollutants via SCR technology |

| Metallurgy | High-temperature furnaces | Improves energy efficiency |

In modern technology, honeycomb catalysts serve very important means through which good industrial practices ensure the betterment of the environment. By its structure, there is efficiency in gas flow that will result in catalytic reactions. These are thereby important in recent modern technologies of emission controls.

Conclusion:

Hence, honeycomb catalysts form the bedrock for establishing clean, efficient industrial processes. Indeed, these have a host of useful applications and therefore find a place of pride for being indispensable for industries looking toward emission reduction with improved catalyzed reactions. As environmental regulations are increased manifold with each passing day, the requirement for honeycomb catalysts too will increase so as to build further on this position in sustainable industrial practices.