Automotive coatings give vehicles that stunning glossy finish while providing protection against corrosion, weathering, and wear. But did you know that these coatings also release harmful volatile organic compounds (VOCs) during application and drying? As environmental standards tighten, there’s a pressing need to reduce VOC emissions in automotive manufacturing. How can advanced VOC catalysts help meet these demands while keeping up with high-quality coating standards?

In this post, we’ll explore the role of VOC catalysts in automotive coatings, how they work to reduce emissions, and why they are critical to a cleaner, more sustainable automotive industry.

What Are VOCs in Automotive Coatings, and Why Are They Harmful?

VOCs are carbon-based chemicals that evaporate easily at room temperature. They are commonly used in automotive coatings to aid in application, drying, and adhesion. However, when VOCs are released into the air, they react with other pollutants and sunlight to create ground-level ozone—a primary component of smog.

VOC emissions have significant health impacts, including respiratory issues, eye irritation, and in some cases, long-term effects on the liver and kidneys. They also contribute to air pollution and climate change. For automotive manufacturers, reducing VOC emissions is not just an environmental imperative but also a regulatory requirement.

How Do VOC Catalysts Work in Automotive Coating Applications?

VOC catalysts are specialized materials designed to break down VOC emissions from automotive coatings into harmless compounds, typically carbon dioxide (CO₂) and water (H₂O), before they reach the atmosphere. They are placed in exhaust systems or integrated into the manufacturing line where VOCs are most likely to be released.

Here’s how VOC catalysts work:

- Adsorption: VOCs pass over the surface of the catalyst, where they are adsorbed.

- Oxidation: The catalyst triggers a reaction that oxidizes VOCs at relatively low temperatures.

- Emission of Harmless Compounds: The oxidation reaction transforms VOCs into less harmful substances, primarily water vapor and carbon dioxide.

By converting harmful VOCs into innocuous emissions, VOC catalysts reduce the environmental impact of automotive coatings and improve the air quality within manufacturing facilities.

The Role of Advanced VOC Catalysts in Reducing Emissions

With advances in catalytic technology, VOC catalysts are now more effective, efficient, and versatile. They can target a broader range of VOCs while operating at lower temperatures, making them more energy-efficient. Here are some of the cutting-edge improvements in VOC catalysts:

- Improved Reaction Efficiency: Modern VOC catalysts can oxidize VOCs at lower temperatures, which reduces energy consumption and allows for faster reaction times.

- Higher Durability: Advances in materials science have resulted in more durable catalysts that withstand harsh conditions, ensuring longer operational life.

- Selective Catalysis: Some VOC catalysts are engineered to selectively target certain VOCs found in automotive coatings, making them more precise and effective.

These advancements make VOC catalysts an increasingly valuable tool for the automotive industry as it seeks to comply with strict emissions regulations.

What Types of VOC Catalysts Are Used in Automotive Coating Applications?

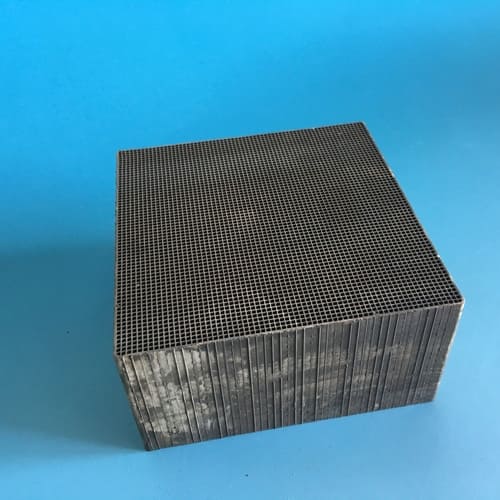

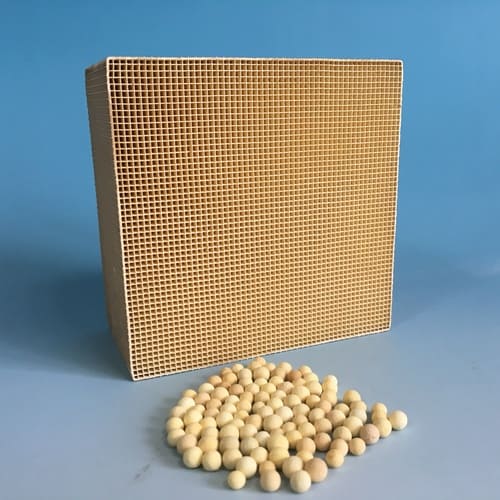

Different types of VOC catalysts are available, each with specific benefits suited to various stages of automotive coating processes. The three primary types include:

- Platinum-Based Catalysts: Known for their high activity levels, platinum catalysts work well at lower temperatures and are highly efficient at breaking down VOCs. They are often used in processes where VOC concentrations are lower.

- Palladium-Based Catalysts: Palladium catalysts are versatile and effective at higher temperatures. They are suitable for processes where VOC emissions are dense or concentrated, such as in paint curing lines.

- Zeolite-Based Catalysts: Zeolite-based VOC catalysts are less expensive and highly porous, making them effective at adsorbing large quantities of VOCs. They are commonly used in combination with metal-based catalysts for enhanced performance.

Each type of catalyst has a unique role in VOC control, allowing automotive manufacturers to tailor emissions-reduction strategies to their specific needs.

Questions About VOC Catalysts in Automotive Coatings

How Effective Are VOC Catalysts in Reducing Emissions?

VOC catalysts are highly effective, with many systems achieving up to 99% VOC reduction in automotive coating processes. These catalysts capture and convert VOCs in real-time, helping manufacturers meet emissions standards without disrupting production workflows.

What Makes Advanced VOC Catalysts Different?

Unlike older catalyst designs, advanced VOC catalysts are engineered for higher selectivity and durability. They can target specific VOC compounds and operate under varying conditions, making them adaptable to modern automotive coating lines that require precision and resilience.

Are VOC Catalysts Cost-Effective?

The initial cost of VOC catalyst installation may be high, but their efficiency, durability, and reduced operational costs over time make them a worthwhile investment for manufacturers. Additionally, the ability to meet regulatory standards helps manufacturers avoid potential fines and operational restrictions.

How Do VOC Catalysts Impact Coating Quality?

VOC catalysts do not interfere with the application or quality of automotive coatings. Instead, they are positioned in exhaust systems, so coatings are applied as usual, while VOC emissions are safely managed post-application. This setup ensures high-quality finishes without compromising environmental goals.

More Questions About VOC Catalyst Benefits

Can VOC Catalysts Help Meet Stricter Emissions Regulations?

Yes, VOC catalysts are instrumental in helping manufacturers meet global emissions standards like the EPA’s Clean Air Act in the United States and Euro 6 in Europe. These regulations set strict limits on VOC emissions from automotive and industrial applications, with penalties for non-compliance.

What Other Environmental Benefits Do VOC Catalysts Offer?

Beyond VOC reduction, advanced VOC catalysts help reduce greenhouse gas emissions by converting VOCs into carbon dioxide and water vapor rather than other hazardous compounds. This process indirectly reduces the carbon footprint of automotive manufacturing.

Are There Alternatives to VOC Catalysts for Reducing Emissions?

While water-based coatings and powder coatings have gained popularity for their low VOC content, they do not entirely replace traditional solvent-based coatings in certain applications. VOC catalysts provide an additional layer of protection, capturing residual VOCs regardless of the coating type used.

How Often Should VOC Catalysts Be Maintained?

Regular maintenance is essential for ensuring VOC catalyst efficiency, though advanced catalysts are designed to be low-maintenance. In most cases, manufacturers schedule annual or biannual inspections to check catalyst activity levels and structural integrity.

Conclusion

Advanced VOC catalysts are transforming the way the automotive industry tackles emissions, particularly from coatings. By converting harmful VOCs into harmless byproducts, these catalysts play a crucial role in reducing pollution and supporting regulatory compliance. As environmental standards continue to tighten, automotive manufacturers will increasingly rely on VOC catalysts to meet emissions targets and create a more sustainable future.

Investing in advanced VOC catalysts not only helps protect the environment but also enhances the longevity of manufacturing equipment and promotes healthier workspaces. In this fast-evolving field, VOC catalysts represent a promising solution that benefits both the industry and the planet.