Are you in the market for a new catalytic converter but feeling overwhelmed by all the options? Look no further, as we take a deep dive into the world of ceramic vs metallic catalytic converters, providing you with the information you need to make an informed decision.

When it comes to choosing the right catalytic converter, there are several factors to consider. One of the most important is the material of the converter. Ceramic and metallic converters each have their own advantages and drawbacks, making it essential to understand the differences between the two.

In this comprehensive guide, we will compare ceramic and metallic catalytic converters on various aspects such as performance, durability, cost, and environmental impact. We will discuss the pros and cons of each type, giving you a clear understanding of which option might be the best fit for your vehicle and driving needs.

Whether you are a car enthusiast or simply looking to comply with emissions regulations, this article will equip you with the knowledge you need to confidently choose the right catalytic converter. So, let’s dive in and explore the world of ceramic and metallic options!

The Role of Catalytic Converters in Reducing Emissions

Catalytic converters are an essential component of a vehicle’s exhaust system. They play a crucial role in reducing harmful emissions and minimizing the impact of vehicles on the environment. Catalytic converters work by converting harmful gases produced during combustion into less harmful substances before they are released into the atmosphere.

The main function of a catalytic converter is to reduce three primary pollutants: nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC). These pollutants are harmful to both human health and the environment. By using various catalysts, catalytic converters facilitate chemical reactions that convert these pollutants into less harmful substances such as nitrogen, carbon dioxide, and water vapor.

Without a properly functioning catalytic converter, vehicles would release significantly higher levels of pollutants into the air, contributing to air pollution and global warming. Therefore, it is crucial to choose the right catalytic converter for your vehicle to ensure optimal performance and environmental compliance. Now, let’s explore the two main types of catalytic converters: ceramic and metallic.

Types of Catalytic Converters – Ceramic and Metallic

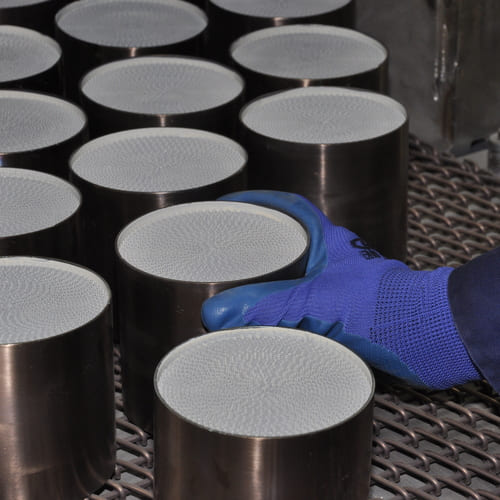

Catalytic converters come in different types, but the two most common ones are ceramic and metallic converters. Ceramic catalytic converters are made of a ceramic monolith coated with a catalyst, while metallic catalytic converters use a metal substrate, often made of stainless steel, coated with a catalyst.

Both types of catalytic converters have their unique characteristics and performance attributes. Understanding the advantages and disadvantages of ceramic and metallic converters will help you make an informed decision when choosing the right one for your vehicle.

Ceramic Catalytic Converters: Advantages and Disadvantages

Ceramic catalytic converters have been in use for several decades and are known for their excellent overall performance. The ceramic monolith used in these converters provides high surface area, which promotes efficient catalytic reactions and improves pollutant conversion rates.

One of the key advantages of ceramic catalytic converters is their ability to withstand high temperatures. The ceramic material is heat resistant, allowing the converter to operate at high temperatures without the risk of damage. This makes ceramic converters ideal for vehicles with high-performance engines that generate more heat during combustion.

In addition to their temperature resistance, ceramic catalytic converters are also known for their durability. The ceramic material is less prone to corrosion, which extends the lifespan of the converter. Furthermore, ceramic converters are generally lighter in weight compared to metallic converters, which can contribute to improved vehicle performance and fuel efficiency.

However, ceramic catalytic converters also have some drawbacks. One major disadvantage is their susceptibility to thermal shock. Sudden temperature changes can cause the ceramic material to crack or break, rendering the converter ineffective. Additionally, ceramic converters tend to be more expensive than metallic converters, which can be a significant factor for budget-conscious consumers.

Metallic Catalytic Converters: Advantages and Disadvantages

Metallic catalytic converters, on the other hand, offer their own set of advantages and disadvantages. One of the key benefits of metallic converters is their resistance to thermal shock. The metal substrate used in these converters can better withstand sudden temperature changes, reducing the risk of damage.

Metallic converters are also generally more affordable compared to ceramic converters. The stainless steel substrate used in metallic converters is less expensive than the ceramic material, making these converters a cost-effective option for many vehicle owners.

In terms of performance, metallic catalytic converters can be just as effective as ceramic converters. The metal substrate provides good surface area for catalytic reactions, allowing for efficient pollutant conversion. However, metallic converters may not perform as well as ceramic converters at very high temperatures.

Despite their advantages, metallic catalytic converters have some drawbacks. They are generally heavier than ceramic converters, which can have a slight impact on vehicle performance and fuel efficiency. Metallic converters are also more prone to corrosion, especially in areas with high levels of moisture or salt.

Factors to Consider When Choosing a Catalytic Converter

When choosing between ceramic and metallic catalytic converters, it is important to consider several factors that can influence your decision. These factors include performance, durability, cost, and environmental impact.

Performance: Consider the specific performance requirements of your vehicle. If you have a high-performance engine that generates a lot of heat, a ceramic converter may be the better choice due to its temperature resistance. However, if your vehicle operates within normal temperature ranges, a metallic converter can provide sufficient performance.

Durability: Evaluate the durability of the converter. Ceramic catalytic converters are generally more durable and resistant to corrosion, making them a good option for long-term use. Metallic converters, while less durable, can still provide satisfactory performance if maintained properly.

Cost: Consider your budget when choosing a catalytic converter. Ceramic converters are typically more expensive due to the higher cost of the ceramic material. Metallic converters offer a more affordable option for those on a tight budget.

Environmental Impact: Consider the environmental impact of your choice. Both ceramic and metallic converters contribute to reducing emissions, but ceramic converters generally offer better overall pollutant conversion rates. If minimizing your vehicle’s impact on the environment is a top priority, a ceramic converter may be the preferred choice.

By carefully considering these factors, you can make an informed decision that aligns with your vehicle’s needs and your personal preferences.

Comparing the Performance of Ceramic and Metallic Catalytic Converters

When it comes to performance, both ceramic and metallic catalytic converters have their own strengths. Ceramic converters are known for their excellent heat resistance, making them a popular choice for high-performance vehicles. They can withstand extreme temperatures without losing their efficiency, ensuring optimal performance even under demanding driving conditions.

On the other hand, metallic converters are praised for their superior flow characteristics. They allow for better exhaust gas flow, reducing backpressure and improving overall engine performance. This can result in increased horsepower and torque, making metallic converters a preferred option for those looking to maximize their vehicle’s performance.

However, it’s important to note that the choice between ceramic and metallic converters ultimately depends on your specific needs and priorities. If you prioritize heat resistance and durability, ceramic converters are the way to go. On the other hand, if you’re looking for improved engine performance and increased power, metallic converters may be a better fit.

In terms of emissions reduction, both ceramic and metallic converters are designed to effectively reduce harmful pollutants emitted by vehicles. They work by converting toxic gases such as carbon monoxide, nitrogen oxides, and hydrocarbons into less harmful substances through a series of chemical reactions.

Environmental Impact of Ceramic and Metallic Catalytic Converters

When it comes to the environmental impact, ceramic and metallic catalytic converters differ in their composition and manufacturing process. Ceramic converters are made from a combination of ceramic materials, such as aluminum oxide and silicon carbide, which are known for their heat resistance and durability.

The production of ceramic converters involves high-temperature kiln firing, which can contribute to greenhouse gas emissions. Additionally, the mining and extraction of raw materials for ceramic converters can have negative environmental effects. However, it’s worth noting that ceramic converters are often more durable and have a longer lifespan compared to metallic converters, reducing the overall impact on the environment.

On the other hand, metallic converters are typically made from a combination of metals such as stainless steel and nickel. The manufacturing process of metallic converters involves welding and forming metal components, which can have its own environmental implications. However, metallic converters are generally more recyclable compared to ceramic converters, making them a more sustainable option in terms of end-of-life disposal.

In recent years, there has been an increasing focus on developing more eco-friendly catalytic converter materials. Researchers are exploring alternative materials, such as zeolites and metal-organic frameworks, which have the potential to improve the efficiency of the catalytic conversion process while minimizing environmental impact.