The world of emission control is ever-evolving, and businesses relying on diesel engines must keep pace with the latest advancements in Diesel Particulate Filter (DPF) technology. Are you curious about the innovations that could revolutionize your fleet’s performance? Wondering how these advancements can make a difference for your business and the environment? Look no further; we’ve got you covered.

In this article, we’ll explore the cutting-edge innovations in DPF technology that businesses need to be aware of. From advanced filtration materials to intelligent regeneration systems, these innovations offer promising solutions for enhanced performance, compliance with emission standards, and more sustainable operations.

What Are the Key Innovations in DPF Technology?

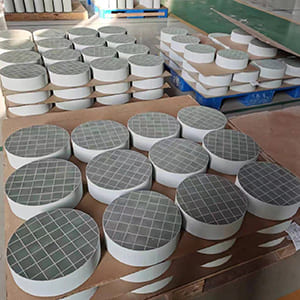

1. Advanced Filtration Materials: Innovations in filtration materials, such as silicon carbide (SiC) and novel metal alloys, improve the efficiency and durability of DPFs. These materials can withstand higher temperatures, allowing for more effective regeneration and longer service life.

2. Integrated Sensors and Monitoring Systems: Intelligent DPFs equipped with sensors and monitoring systems can provide real-time data on filter efficiency, soot accumulation, and temperature. This data enables businesses to optimize performance and plan maintenance proactively.

3. Active Regeneration Technology: Active regeneration systems use electric or fuel-based heaters to initiate the regeneration process, even at low exhaust temperatures. This ensures continuous filter cleaning and reduces the likelihood of manual intervention.

4. Coated Filters: Innovative coatings on DPF surfaces can enhance filtration efficiency and reduce the buildup of harmful substances. These coatings also enable passive regeneration at lower temperatures.

5. Onboard Diagnostics (OBD) Integration: OBD systems integrated with DPFs offer better engine management and diagnostics, ensuring the optimal functioning of both the engine and the DPF.

How Do These Innovations Benefit Businesses?

Improved Performance: Innovations in DPF technology lead to more efficient filtration and lower exhaust backpressure, resulting in improved engine performance and fuel economy.

Regulatory Compliance: Advanced DPFs help businesses meet ever-stringent emission regulations, avoiding fines and ensuring smooth operations in regions with strict environmental standards.

Extended Service Life: DPF innovations, such as durable filtration materials and advanced regeneration systems, can extend the lifespan of the filter, reducing maintenance costs.

Enhanced Sustainability: Embracing innovative DPF technology contributes to a business’s sustainability efforts, showcasing environmental responsibility to stakeholders and customers.

What Does the Future Hold for DPF Technology?

The future of DPF technology promises even more exciting innovations, including:

- Nanostructured filtration materials for higher efficiency and lower pressure drop.

- Integration with hybrid and electric vehicle systems.

- Enhanced connectivity for remote monitoring and predictive maintenance.

Conclusion

As emission regulations become more stringent, businesses must stay ahead of the curve by adopting the latest innovations in DPF technology. These advancements offer numerous benefits, from improved engine performance and regulatory compliance to extended service life and enhanced sustainability. Embracing the future of DPFs can elevate your business’s performance while contributing to a greener and more sustainable world. Stay informed, stay efficient.