Are you on the hunt for the perfect Diesel Particulate Filter (DPF) for your engine? Do the complexities of cordierite DPFs leave you perplexed? Or perhaps, you’re simply curious about this technology that’s pivotal in curbing air pollution from diesel engines? If these questions strike a chord, you’re in the right place.

In this blog post, we’re addressing the most Frequently Asked Questions (FAQs) about cordierite DPFs. Cordierite DPFs, a vital part of modern emission control systems, help trap and burn particulate matter, thereby reducing harmful emissions. Their properties, such as high thermal shock resistance and relatively lower cost, make them a popular choice in a range of applications, from passenger cars to stationary generators. But the world of cordierite DPFs can be complex, with numerous factors to consider such as filtration efficiency, backpressure, regeneration cycles, and more.

Stay tuned as we explore these nuances, answer the most commonly asked questions, and help you gain an in-depth understanding of cordierite DPFs.

What are Cordierite DPFs and Why are They Important?

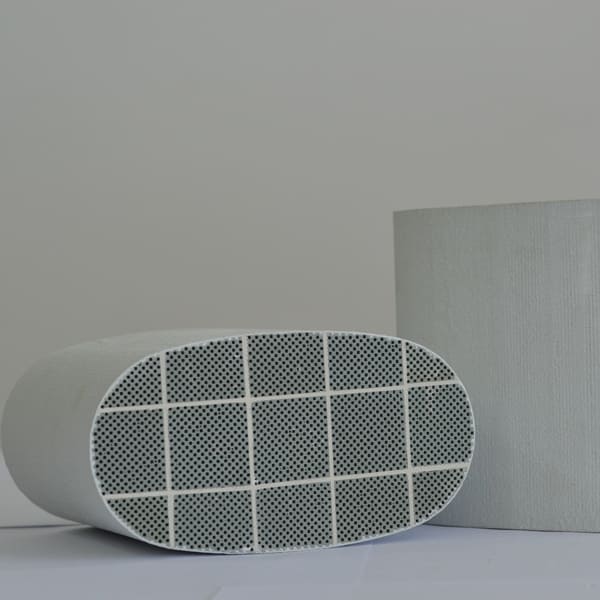

Cordierite DPFs are a type of Diesel Particulate Filter made from a ceramic material called cordierite. They are crucial in reducing particulate matter emissions from diesel engines, helping to meet stringent emission regulations and combat air pollution.

What Sets Cordierite DPFs Apart from Other Types of DPFs?

Cordierite DPFs are renowned for their high thermal shock resistance and cost-effectiveness. However, while they can withstand normal regeneration temperatures, they are vulnerable to melting under extreme temperatures. Other types of DPFs, like silicon carbide DPFs, can resist higher temperatures but are more expensive.

How Do Cordierite DPFs Work?

Cordierite DPFs function by trapping soot particles in the exhaust gas as it passes through the filter. Over time, this soot builds up and needs to be burnt off in a process known as regeneration.

What is Regeneration and Why is it Necessary?

Regeneration is the process of burning off the accumulated soot in the DPF. Without regular regeneration, the DPF can become blocked, leading to increased exhaust backpressure and potential engine damage.

What are the Differences between Symmetric and Asymmetric Cordierite DPFs?

Symmetric DPFs have an equal number of inlet and outlet channels, while asymmetric DPFs have larger inlet channels and smaller outlet channels. This difference influences the DPF’s soot loading capacity, backpressure, and regeneration frequency.

How do I Maintain a Cordierite DPF?

Proper maintenance involves regular regeneration to burn off accumulated soot. It’s also crucial to use low ash engine oil to prevent ash build-up, which cannot be burnt off during regeneration.

Conclusion

Understanding cordierite DPFs is essential in choosing the best emission control solution for your engine. These DPFs, with their unique properties and cost-effectiveness, have a critical role in reducing particulate emissions. The choice between symmetric and asymmetric designs, the importance of regular regeneration, and appropriate maintenance practices are all vital facets of cordierite DPF knowledge. Armed with these insights, you’re now well equipped to navigate the world of cordierite DPFs.