Have you ever wondered what goes behind designing the most effective Diesel Particulate Filter (DPF)? Are you torn between choosing a symmetric or an asymmetric cordierite filter for your engines? Do you ponder about what makes these two designs different and which one is most suitable for your needs? We’ve all been there, deliberating on these complex questions.

In the quest to design the ideal DPF, understanding the different types of filters – namely symmetric and asymmetric cordierite filters – is critical. Symmetric filters, with their equal inlet and outlet channels, have been the go-to choice for many due to their high filtration efficiency and affordability. However, asymmetric filters, with their distinctive large inlet and smaller outlet channels, are gaining popularity due to their larger soot capacity, reduced backpressure, and potentially longer service intervals. The choice between symmetric and asymmetric designs revolves around factors such as soot load, required filtration efficiency, engine performance, and cost considerations.

While this may feel overwhelming, we aim to simplify this complex topic. We’ll delve deeper into the intricate world of cordierite DPFs and help you understand which design is the perfect fit for your needs.

What is the Core Difference between Symmetric and Asymmetric Cordierite Filters?

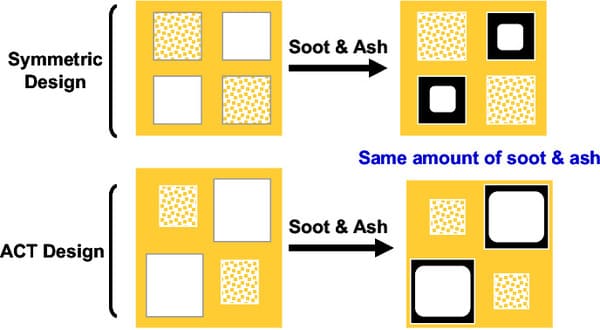

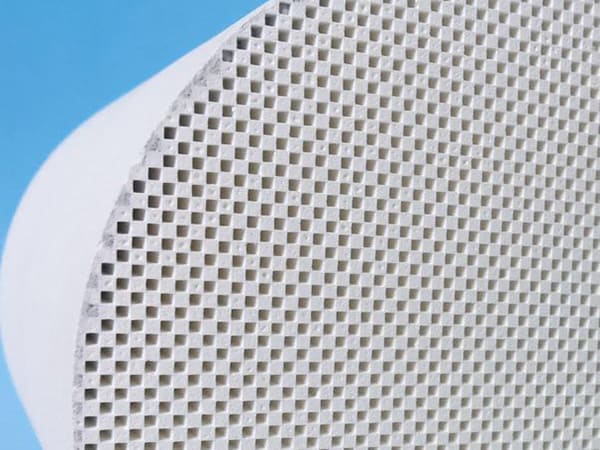

The fundamental difference between symmetric and asymmetric cordierite DPFs lies in their structure. Symmetric DPFs utilize a honeycomb structure with an equal number of inlet and outlet channels. The exhaust gas is forced to pass through the cell wall, where the soot is captured, before it can exit through the neighboring cell.

On the other hand, asymmetric DPFs or Asymmetric Cell Technology (ACT) filters have larger inlet channels and smaller outlet channels. This structural difference increases the filter’s soot loading capacity, potentially reducing the frequency of regeneration cycles and the backpressure on the engine.

How does the choice between Symmetric and Asymmetric Impact Engine Performance and Fuel Efficiency?

Engine performance and fuel efficiency are directly impacted by the backpressure created by the DPF. Symmetric DPFs, with their wall-flow design, can create substantial backpressure, potentially affecting the engine’s performance and fuel efficiency.

Conversely, the larger inlet channels in asymmetric DPFs reduce this backpressure, thereby potentially enhancing overall engine performance and fuel efficiency. These benefits, however, come with a trade-off in the form of a slightly lower filtration efficiency compared to symmetric filters.

How Frequently Do Symmetric and Asymmetric Filters Require Regeneration?

Regeneration frequency is a critical aspect in DPF maintenance. Due to their design, symmetric DPFs may require more frequent regeneration cycles. However, the asymmetric DPFs with their larger inlet channels offer an increased soot loading capacity, which can reduce the frequency of regeneration cycles. This might be beneficial in applications where reduced maintenance downtime is a priority.

Conclusion

Choosing between symmetric and asymmetric cordierite DPFs is not a one-size-fits-all decision. It requires a thorough understanding of the application, the expected soot load, the necessity for backpressure reduction, and cost implications. Asymmetric DPFs, with their potential for better engine performance and less frequent regenerations, might appeal to those prioritizing operational efficiency. In contrast, symmetric DPFs might be the choice for those seeking high filtration efficiency at a lower cost. Remember, the ideal DPF design is the one that best fits your specific needs.