Have you ever wondered how to optimize your industrial process by making the best choice of a monolithic catalyst? Is it baffling to navigate the plethora of choices available in the market? Are you concerned about whether your investment in a monolithic catalyst will yield the desired results? If you’ve pondered these questions, this blog post is for you.

In the world of industrial chemistry, choosing the right monolithic catalyst is essential to ensure efficient and effective toluene treatment. The choice is pivotal to various aspects of your operations, including cost-efficiency, environmental sustainability, and adherence to regulatory standards. Moreover, the right catalyst can significantly impact the final quality of the products. But how do you make that choice? What factors should you consider?

Your journey to making the right choice begins here. Keep reading to discover more.

What is the Role of a Monolithic Catalyst in Your Process?

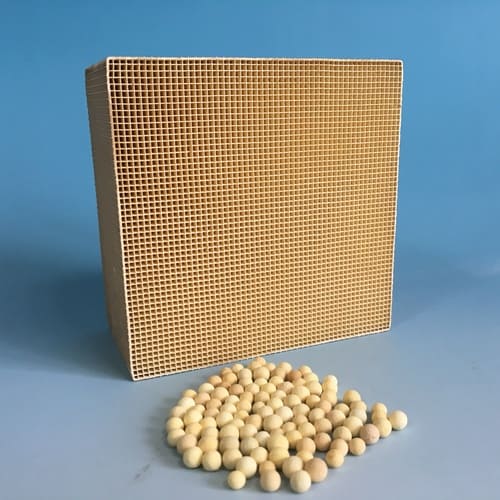

The primary function of a monolithic catalyst is to facilitate chemical reactions, increasing their speed and efficiency. Their unique design, often resembling a honeycomb structure, provides a high surface area for the reactions, making them particularly effective. Monolithic catalysts can help in the conversion of acetone, ethyl acetate and toluene into safer and more environmentally friendly substances, which is a key requirement in industries such as paint manufacturing, adhesives, and automotive.

How Do You Determine the Right Monolithic Catalyst?

Choosing the right monolithic catalyst requires a deep understanding of your industrial needs, the nature of the reactions, and the potential impact on the environment. Here are some factors to consider:

- Catalyst Efficiency: The catalyst should effectively increase the reaction rate while reducing energy consumption. Check data sheets for information about the catalyst’s performance under various conditions.

- Compatibility: The catalyst should be compatible with your existing industrial processes. A misfit could lead to process inefficiencies and additional costs.

- Regulatory Compliance: The chosen catalyst should comply with all relevant environmental and safety regulations. Non-compliance could lead to hefty fines and damage to your business’s reputation.

- Lifecycle Cost: Consider the total cost of owning the catalyst, including purchase price, operating cost, maintenance, and disposal. A cheaper catalyst might have higher operating costs, making it more expensive in the long run.

- Supplier Reputation: The manufacturer or supplier of the catalyst should have a reputation for quality and reliability. Check reviews and ask for references before making a purchase.

What Are Some Reliable Sources for Monolithic Catalysts?

Several reputable manufacturers produce high-quality monolithic catalysts. Before choosing a supplier, it’s advisable to conduct a thorough market survey and comparison. Websites such as SKY emission can provide a monolithic catalysts. Consider suppliers’ certifications, product range, customer reviews, and their willingness to provide after-sales support.

Can You Customize Monolithic Catalysts for Specific Industrial Applications?

Yes, some manufacturers offer customization services. They can design and manufacture a catalyst tailored to your specific industrial needs. Customization can lead to significant improvements in process efficiency and cost savings. However, keep in mind that customization might require a larger initial investment.

Conclusion

Choosing the right monolithic catalyst for your industrial needs is a complex task. It requires careful consideration of your specific process requirements, regulatory compliance, cost factors, and supplier reputation. But making the right choice can lead to significant improvements in efficiency, cost savings, and environmental sustainability. Start your journey to finding the right monolithic catalyst today and experience the transformation in your industrial process.

Remember, knowledge is power. Equip yourself with the right information, ask the right questions, and make an informed choice. Your ideal monolithic catalyst is out there, waiting to revolutionize your industrial process.